Photo:Gunma Prefecture

Photo:Gunma Prefecture

- Woven textiles

- Gunma

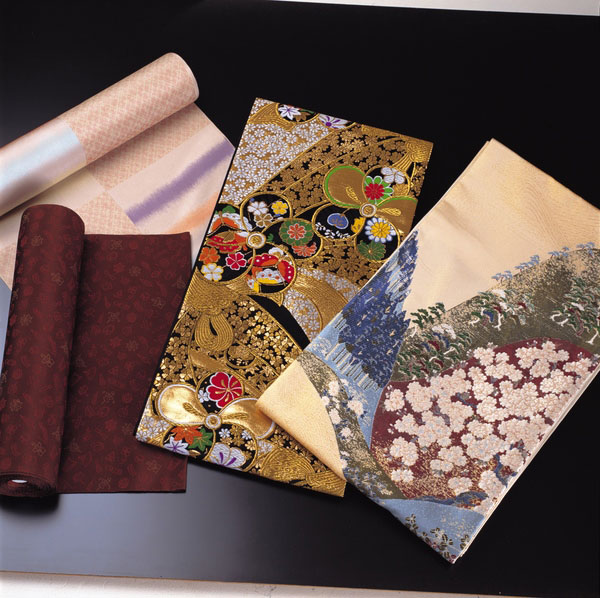

Kiryu brocade Kiryu ori

Classic textile with 1300 years of history

Seven prominent weaving techniques

Description

What is Kiryu brocade ?

Kiryu brocade (called Kiryu ori in Japanese) is a woven cloth produced in the city of Kiryu, Gunma prefecture. This area has a lush environment with excellent climate and terrain, helping it to be prosperous in the silk industry for years. Kiryu is so famous for textiles production that Jomo karuta, a version of a card matching game called karuta with historically significant places and things specific to Gunma, includes a card listing the city as a famous production area.

This craft has seven weaving techniques: Omeshi ori (silk crepe), Yokonishiki ori (horizontally woven brocade), Tatenishiki ori (vertically woven brocade), Futsu ori (airy weave), Ukitate ori (raised pattern weave), Tatekasurimon ori (vertically splash-pattern weave), and Mojiri ori (layered fabric). Kiryu brocade fabrics are widely used for luxury kimono and decorative accessories because of their soft texture. In the past, Kiryu was famous throughout Japan for its silk production and textiles contributions. Now, the city has been pursuing the invigoration of the local textile industry.

History

There is an old saying, “Nishijin in the west, Kiryu in the east” denoting Kiryu brocade as possessing equal prestige and history as Nishijin brocade, a fabric produced in Kyoto, west of Kiryu. Both Nishijin and Kiryu brocade have been in production for at least a thousand years. Kiryu's history as a thriving textile production area can be seen with written records from the year 714 describing the presentation of a textile called Ki ashiginu to the Imperial Court.

It is local legend that a man from Yamada district (current day Kiryu) was sent to serve as an official at the Imperial Court. While working there, he fell in love with Princess Shirataki. The man successfully got the Imperial Court to grant him permission to marry the princess. After marrying, the two lived together in his hometown where the princess, knowledgeable about sericulture and weaving, started teaching the locals. Kiryu brocade rose to prominence across Japan on par with Nishijin brocade, and Kiryu fabrics were found in the belongings of prominent warlords such as Yoshisada NITTA and Takauji ASHIKAGA.

Later in the Edo period (1603-1868), Kiryu brocade began gaining momentum as an industry. The founding of Nihon Orimono Corporation in 1887 led to successful industrialization, allowing this craft to establish a dominant place in Japan’s weaving industry. In 1977, Kiryu ori was recognized as a traditional craft.

General Production Process

- 1. Thread making Raw silk threads will be prepared for weaving. The types of silk threads will vary based on whether they are used for warp (parallel) or weft (perpendicular) threads.

- 2. Dyeing Refinement is the process of boiling raw silk in hot water for an hour so that impurities are removed. Then, the silk threads are dyed in specific colors based on what the design will become. With double the amount of weft threads, a sizing liquid is rubbed in to keep the threads twisted during the next step.

- 3. Twisting

Nenshi is a process of twisting extremely fine silk threads to increase their strength. A traditional speciality machine is used to give the threads a firmer twist, with two thousand twists per meter. Twisted silk threads undergo reeling in preparation for warping and spooling.

- 4. Warping and spooling

Warping is when the length of threads is adjusted to the amount required for weaving a bolt of cloth. Spooling is the wrapping of weft threads around a wooden tube called a spindle. Reeled silk threads are wound onto the wooden tube manually, mechanically, or automatically.

- 5. Designing and card punching

Once the threads have been prepared, the kimono is designed. A design pattern is traced on special graph paper and holes are punched on a paper according to the design pattern. These holes specify the positions for the warp and the weft threads to go up and down.Today, technology is used for this process and a design is created on a computer, saved as image data, and directly sent to a loom for weaving. Computerization has expanded design options and led to an even wider range of patterns for Kiryu brocade fabrics.

- 6. Preparation of Jacquard loom

A Jacquard loom is a weaving machine invented by Frenchman Joseph Marie Jacquard in 1806. It started to be used for Kiryu brocade production after being imported by Kiroku SABA, the president of Nippon Textile Corporation, in 1886. The loom sends design data from plotting paper or a computer to a heddle (which raises and lowers warp threads). Then, a pattern is created by the loom controlling the threading of warp threads.

- 7. Weaving Through the use of a Jacquard loom, a large variety of patterns can be woven. However, Kiryu brocade can be categorized into seven weaving techniques and the commonality is that pre-dyed threads are woven. The quality of the completed brocade is carefully inspected by the artisans.

- 8. Developing texture The brocade is placed in boiling water in order to remove any remaining glue from the weft threads. This leads to soft wrinkles developing and leading to a crepe texture called shibo.

- 9. Finishing touches Once the fabric has been refined in boiling water, a wooden mallet is used to strike and remove the wrinkles as it causes unevenness. Then, after inspecting the brocade for any defects or stains and mending any flaws, the piece is complete. Kiryu brocade is always sold with an official seal of authenticity designating it as an traditional craft. Artisans are able to demonstrate their great skill by creating fabric with a painting on it. Their techniques continue to attract new admirers of Kiryu brocade, even now.

Where to Buy & More Information

Morihide Orimono Sankokan・Yukari

-

Address

-

Tel.+81-277-45-3111

-

ClosedMondays

-

Business Hours10am to 4pm

-

Website

See more Woven textiles

- Nishijin brocade

- Yuki tsumugi silk

- Kurume traditional resist-dyed textiles

- Ojiya chijimi textiles

- Hakata brocade

- Ushikubi tsumugi silk

- Chichibu-meisen silk

- Miyako ramie textile

- Shiozawa tsumugi silk

- Kumejima tsumugi silk

- Omi ramie cloth

- Ryukyu traditional resist-dyed textiles

- Kiryu brocade

- Murayama-oshima tsumugi silk

- Yumihama traditional resist-dyed textiles

- Chibana-hanaori textiles

- Hon-shiozawa silk

- Oitama tsumugi silk

- Ojiya tsumugi silk

- Yaeyama cotton cloth

- Yaeyama ramie cloth

- Honba oshima tsumugi silk

- Shinshu tsumugi silk

- Shuri brocade

- Tama brocade

- Yomitanzan-hanaori textiles

- Isesaki traditional resist-dyed textiles

- Hachio island silk

- Nibutani bark cloth

- Uetsu tilia bark cloth

- Awa-shijira cotton cloth

- Kijoka banana fiber cloth

- Tokamachi traditional resist-dyed textiles

- Tokamachi akashi chijimi textiles

- Yonaguni brocade

- Yuntanza minsa

- Flower pattern textiles

- Oku-Aizu Showa Karamushi Textiles