Photo:Kochi Prefecture

Photo:Kochi Prefecture

- Traditional Japanese paper

- Kochi

Tosa traditional Japanese paper Tosa washi

A brilliant world with a history of over 1000 years

The combination of nature and craftsmanship

Description

What is Tosa traditional Japanese paper ?

Tosa washi is a kind of traditional Japanese paper made in Kochi prefecture, both in the city of Tosa and around the town of Ino.

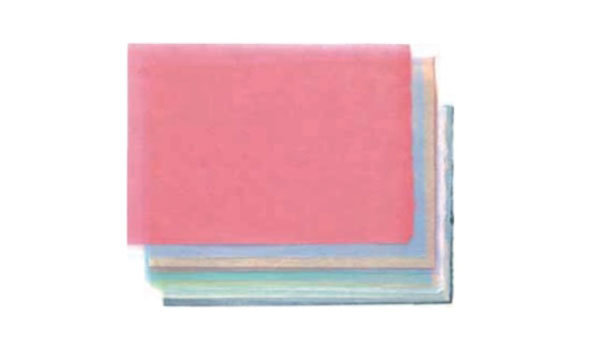

In the past, it was used to make a holder for wallets and medicine or paper lanterns. Now it has a wide range of uses, such as paper collages, fusuma*, packaging for confectionary, or bookmaking. It is a highly regarded paper, not just in Japan but also in other countries, because of its use in restorations of paintings and old documents.

There are many different kinds of Toshi traditional paper but what they have in common is being incredibly thin and strong. A notable example is Tosa tengu-jo which is one of the world's thinnest papers at only 0.03 mm thickness. The thinness and strength comes from being made of paper mulberry and the flowing waters of the Niyodo River that runs through the Tosa area. Tosa traditional paper would not be what it is without the help of natural resources.

The production of many different types of Japanese paper has reduced domestically. However, three hundred different types of Tosa washi continue to be produced even today.

*Fusuma are vertical rectangular panels which can slide from side to side to redefine spaces within a room or act as doors.

History

There are various theories about the history of Tosa washi. Although it is not known for sure, it is thought that a man named Ki no Tsurayuki (872-945) was influential in conveying information about the paper from the year 930. Ki no Tsurayuki was a noted literary court noble and also known as one of the Hyakunin Isshu poets (one hundred classical Japanese poems by one hundred poets) of the Heian period (794-1185). He was appointed to be the provincial governor of Tosa and promoted the paper production industry. It is confirmed that Tosa paper has a history of over one thousand years because during the Heian period it was used to wrap gifts presented to the imperial family as written in ancient documents. At the time, washi was considered precious because it was used to make kai awase, which is a game played by the aristocracy in their leisure time where the pictures pasted onto clam shells are matched,

The use for traditional Japanese paper changed with the eras and it began to be used to make samurai's kimono, dolls, and han bills (provincial money). From the Edo period (1603-1868), Tosa washi began to be viewed as an important specialty product that was used to be gifted to the shogunate (feudal military government) and was also under protection by the Tosa clan. Its traditional role as a specialty product from the Ino-cho and Tosa city region, has been carried to the present day.

Production Process

- 1. Boiling

The basic raw materials for Tosa washi are mainly the bark of three plants: paper mulberry, paperbush and gampi. The method used to make the paper differs slightly according to the quality of the paper or its application. In the case of paper mulberry, the basic method is to separate the white part from the outer black part, wash it, and bleach it in water. After it has been bleached in cold water for a fixed amount of time, the materials are boiled. In order to make beautiful Japanese paper, alkaline solutions, such as soda ash or lime ash, are added and then it is boiled down for two to four hours. By adding alkaline substances, it is possible to extract only the fibers.

- 2. Washing and bleaching

The next step is to rinse the boiled Japanese paper materials in a limpid stream. The work of thinly spreading and washing the materials repeatedly requires a lot of effort and takes a whole day and night. Then the thoroughly washed and rinsed Japanese paper materials are bleached in the sun or by using bleaching liquid. Even materials that are a little discolored due to steaming gradually become white by exposing them to the sun for 3-4 hours.

- 3. Cleaning

Parts of the outer bark or dust particles still remain in the washed and boiled-down raw material. These unwanted pieces must be carefully removed by hand. Properly removing the impurities can help to produce a strong finish to the Japanese paper and make it less likely to have spots or deteriorate as much with age.

- 4. Beating

Rather than spreading the fibers out and beating them, they are rolled into a round ball and beaten with a stick. Recently, machines have been used more often for this work of beating the fibers. The beating is done to make it easier to separate the fibers for papermaking. Fibers that have been firmly beaten spread out easily when placed in water.

- 5. Thinning

Materials that have been sufficiently softened by beating are placed in a thinning basket, which is a small basket filled with water where the fibers are thoroughly separated. This work, called thinning, plays an important role in determining the quality of the paper.

- 6. Papermaking

After the fibers have been properly prepared, a gelatinous substance is added to the fibers to create the proper conditions for papermaking. This gelatinous thickener, called neri and made from a plant called aibika, is put into the water while loosening the fibers in the raw material. The correct amount of neri is a very important point because if the amount is too small the water is lost and if there is too much, it is impossible to drain when making the paper.

When the gelatinous substance and the fibers are thoroughly mixed together, it is time to start papermaking. There are two processes in papermaking, nagashisuki (papermaking in flowing water), and tamesuki (papermaking using stored water). With nagashisuki, the liquid paper is scooped up in a paper making vat and gently shaken back and forth to give the paper a uniform thickness. The tamesuki technique involves draining the water after scooping up the fibers in the liquid. Since the concentration of the materials changes whilst making the paper, attention must be paid toward making all the paper an equal thickness.

- 7. Dehydration

Next, the water is thoroughly drained from the papermaking materials. Weights are placed on top of the sheets of paper made and after being left overnight, are dehydrated in a compressor. Until recently, a lever was used.

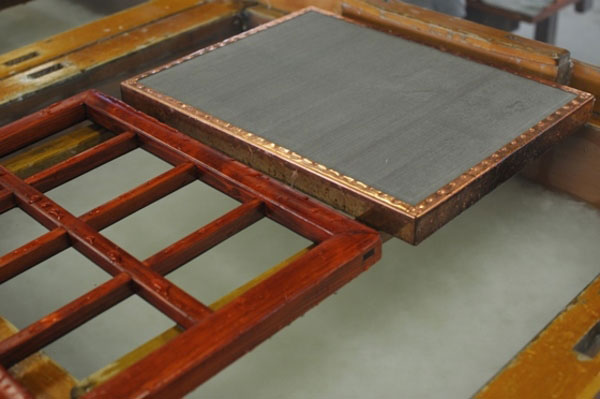

- 8. Drying

After dehydration is completed, the Tosa paper is thoroughly dried. There are currently two methods used to dry the paper: drying in the sun and thermal drying. For sun-drying, which is used most often, each piece of paper is carefully spread on a drying board and dried in the sunlight.

- 9. Cutting and packing

The paper becomes suitable for usage after being carefully aligned and cut down to size. Then, once trimmed, the Tosa washi must be put into bundles for shipping. One bundle of washi is two hundred sheets in sets of ten. The two thousand sheets of paper in one unit are packaged and the trading unit for packing is known as a maru or round.

Facility Information

Inocho Paper Museum

-

Address

-

Tel.+81-88-893-0886

-

ClosedMondays (open if Monday is holiday and closed the next day) and December 27 to January 4 (open January 2 and 3)

-

Business Hours9am to 5pm

-

Website

Other Traditional Japanese paper

- Mino traditional Japanese paper

- Echizen traditional Japanese paper

- Tosa traditional Japanese paper

- Sekishu traditional Japanese paper

- Inshu traditional Japanese paper

- Awa traditional Japanese paper

- Ozu traditional Japanese paper

- Echu traditional Japanese paper

- Uchiyama Japanese paper