- Traditional Japanese paper

- Gifu

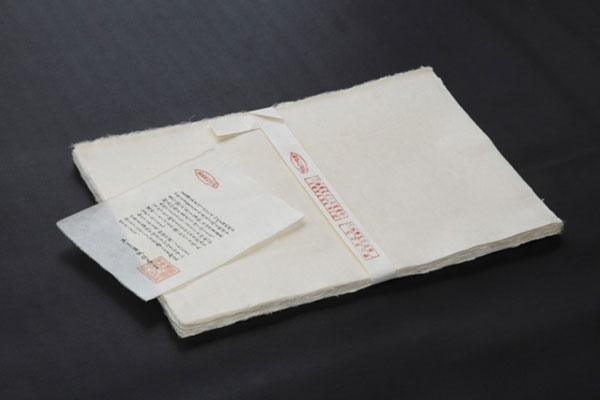

Mino traditional Japanese paper Mino washi

Traditional superior techniques of papermaking

show the harmony of beauty and utility

Description

What is Mino traditional Japanese paper ?

Mino washi is a type of Japanese paper made in Gifu prefecture. Washi is made from paper mulberry which is a plant that grows in the city of Mino, a place of abundant forests. Ancient manuscripts in the Shosoin Repository* indicate the history of papermaking as beginning during the Nara period, and Mino washi was known for its balance of thinness, strength, and beauty. Refined and highly-skilled artisan techniques bring out the very best from the raw materials. During the Edo period, Mino washi was known as being the finest type of washi paper and was used by the Tokugawa shogunate, the feudal military government during this time.

In Gifu prefecture, the Terao region in the city of Seki is especially famous for Mino washi production. Because the quality of paper is largely affected by water quality, the paper texture differs slightly between production regions. Alongside Terao, other areas in Gifu prefecture for high quality Mino washi are Iwasa, Taniguchi and Makidani. Following the success of Mino washi, several handicrafts such as Gifu paper lanterns and umbrellas have started to be manufactured in Gifu prefecture.

*The Shosoin Repository is a building located in Nara, a former capital of Japan, that has been around since the eighth-century. It not only has a collection of treasures dating back to the Silk Road, it also preserves over 10,000 hand-written documents all dating from the Nara period (710–784). Today the repository is under the control of the Imperial Household Agency.

History

Mino washi making likely began in the Nara period, over 1300 years ago, and it became popular nationwide after the Muromachi period (1336-1573). The Toki family, the local military governors of Mino, took many measures to stimulate the local economy; one was to protect the silk-reeling industry, and another was to start a rokusaiichi, a paper market. In response to the measures, the paper industry grew steadily, and since the Toki family were versed in culture and art, several of their associates such as court nobles and priests also took to using Mino washi. Scholars believe this response significantly contributed to Mino washi becoming popular throughout the nation.

During the Edo period, there was the start of a national monopoly system defining local specialties and Mino became an official papermaking region. As a result, Mino paper was used for shoji sliding screen doors which established a ubiquity and brand value for the paper nationwide. While Mino washi was already well-known as a high quality paper, the monopoly system helped make it popular among the chonin social class (rising middle class). Production rapidly expanded and consumers easily associated Mino washi with shoji paper. With the abolition of the monopoly system during the Meiji Restoration in 1868, demand for paper increased even more. During wartime, Mino washi was used not only for daily goods, but also for military use like wadding paper for explosives. After the war, with the import of wood pulp paper, opportunities to use Mino washi naturally declined. However, in 1985, Mino washi was designated as one of the Traditional Crafts by the Ministry of Economy, Trade, and Industry. Craftsmen still uphold traditional handwork skills and produce high-quality Mino washi today.

General Production Process

- 1. Preparation of raw materials

Paper mulberry, a deciduous tree shrub belonging to the mulberry family, features long fibers and is the most commonly used fiber in making Japanese paper. Mino washi is used in a variety of ways such as ceremonial, artistic (calligraphy), and practical (shoji screens). Other trees used for washi are paper bush, generally used to make printing paper with a slick and slightly glossy texture; and ganpi plant, for paper with a glossy texture.

First trees are cut at the base, with enough stock left for them to regrow. Then the wood is stripped of the outer bark and left in piles to dry.

- 2. Bleaching in river water

The dried bark piles are left in a river or tank for about five days to soften and remove impurities.

- 3. Boiling and aging

To help loosen the long fibers, the softened bark is boiled for one to two hours in an alkaline solution, usually made of lime or soda ash. In earlier times, rice hulls or paddy straw was used.

- 4. Cleaning

During this step, hunched-over craftsmen spend hours removing knots and dirt from the boiled down fibers by hand which takes a considerable amount of time. Since how impeccably this process is carried out directly affects the quality of the finished paper, such prolonged cleaning makes an enormous difference in quality, which is what sets Mino washi apart.

- 5. Beating

Cleaned fibers are beaten on a board with a pestle or wooden hammer. To further thin the fibers, a rounded bundle is beaten for about ten minutes. Machines are increasingly used for this process, and fewer craftsmen remain true to this manual tradition.

- 6. Papermaking

Thinned fibers are thrown into a sukibune or a water tank resembling a bathtub, water is added, and a gelatinous mix made from the roots of sunset hibiscus is stirred in. When the right degree of stickiness has been achieved, the pulp is scooped out onto a sukote or wooden screen and gently mixed to prevent fibers from becoming tangled. This process makes the sheet of Mino washi thinner, finer, and stronger.

- 7. Drying

The pulp paper contains plenty of water, so it must be scooped out carefully with a stone or jackscrew. The scooped paper is allowed to partially dry until some 60% has evaporated. The paper sheets containing the remaining 40% of water are carefully laid on a board and left to dry in the sun.

- 8. Finishing

After drying, each sheet is checked by an experienced artisan's eye to thoroughly maintain the highest standards. Surprisingly, only 4% of the original pulpwood finds its way into the finished product of Mino washi. To make such gossamer light and durable paper requires careful and stringent work from start to finish.

Where to Buy & More Information

Mino-Washi No Sato Kaikan

-

Address

-

Tel.+81-575-34-8111

-

ClosedTuesdays (open on Tuesday if it is a holiday and closed on Wednesday), closed the day after a public holiday except for Saturday and Sunday, around the New Year

-

Business Hours9am to 5pm

-

Website

See more Traditional Japanese paper

- Mino traditional Japanese paper

- Echizen traditional Japanese paper

- Tosa traditional Japanese paper

- Sekishu traditional Japanese paper

- Inshu traditional Japanese paper

- Awa traditional Japanese paper

- Ozu traditional Japanese paper

- Echu traditional Japanese paper

- Uchiyama Japanese paper