- Traditional Japanese paper

- Nagano

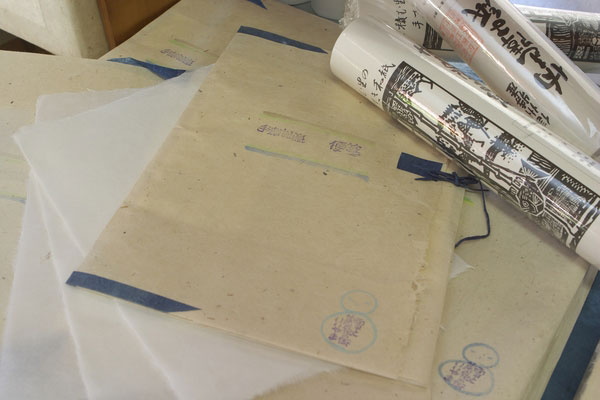

Uchiyama Japanese paper Uchiyama gami

100 % mulberry paper of excellent quality

Supple, smooth, translucent products

Description

What is Uchiyama Japanese paper ?

Uchiyama Gami is a type of traditional Japanese paper made in the Oku-shinano region of northern Nagano prefecture. As a region that gets heavy snowfall during the winter, papermaking production developed to provide supplementary income. This craft uses a hundred percent paper mulberry for its raw material which gives the paper excellent strength, air permeability, translucency, and heat retention. As snowfall in Oku-shinano can be over a meter in one night, paper mulberry bark needs to be harvested by the end of November at the latest. During winter, tree bark fibers are bleached by spreading them on top of the snow. This method, called snow refining, makes use of the ozone that is naturally released by the melting snow. This process where they make use of their natural resources with no chemicals, gives the final product a strength that is capable of withstanding cold and damp weather, and a soft texture. Since it is bleached naturally, Uchiyama gami hardly gets browned from the sun and can be preserved for a long time. Because of this durability, this paper had been used for government resident registers and was also trusted by other government offices. It also has a good reputation as sliding door paper with high translucency, and is suitable for interior crafts such as light shades. It is also widely used as calligraphy paper.

History

Photo:Shinshu・Nagano Prefecture Tourism Association

Photo:Shinshu・Nagano Prefecture Tourism Association

Uchiyama Gami is handmade Japanese paper thought to have originated in the village of Uchiyama, Shinano province (now Nagano prefecture). During the early Edo period (1603-1868), a man named Kiuemon HAGIWARA learned papermaking techniques in Mino province (now Gifu prefecture) and began a papermaking business upon returning to his home in Uchiyama. This is thought to be the origin of this paper. At that time, the raw material of Uchiyama Gami, paper mulberry, naturally grew in the local mountains and was easy to collect, which helped spread production throughout the region. Land tax accounts of the Shinano province from the mid-Edo period indicate that the papermaking industry in Uchiyama was subject to taxation. Since Oku-shinano is a snowy area, production of Uchiyama Gami gradually took root in the region as a wintertime side job. As the paper fetched a high price in the neighboring county of Echigo, it became a valuable cash income source. During the Meiji period (1868-1912), new techniques and mechanization improved production methods. At its peak, there were 1354 material suppliers, 1130 producers, and 175 distributors. Later, the industry declined due to the spread of mass produced machine-made paper. Because of its low production efficiency due to its hand-made nature, the number of artisans gradually dropped. Today, the few workshops that are left preserve the traditional papermaking techniques of Uchiyama Gami.

General Production Process

Photo:Shinshu・Nagano Prefecture Tourism Association

Photo:Shinshu・Nagano Prefecture Tourism Association

- 1. Cultivating paper mulberry

Paper mulberry, a member of the mulberry family, was often found growing near fields of rice or crops. In comparison with other plants used for papermaking in Japan, paper mulberry has long and strong fibers. The plant is cut from the root during November and December when it sheds its leaves.

- 2. Peeling bark and drying

The harvested paper mulberries are cut into lengths of eighty centimeters to a meter, bundled, and steamed in a pot to soften and make the bark easier to remove. The black bark, which is the material for Japanese paper, is peeled off, bundled and hung to dry.

- 3. Freezing and scraping bark

The bark is soaked in water and then laid on the snow overnight to freeze. This is repeated about three times to make the bark easier to peel. A tool called okaki is used to scrape off the scratches on the surface of the bark.

- 4. Bleaching on snow

The black bark is laid out in a snowfield, sprinkled with falling snow, and left to bleach for about a week. The bark is naturally whitened by the ozone released by melting snow. When the bark becomes white, it is left to dry in the sun.

- 5. Boiling and aging

The whitened bark fibers are softened by boiling in a pot of alkaline chemicals such as caustic soda or carbonic acid. In the old days, craftsmen used soda ash, which causes least damage to the fibers. The alkaline ingredients are washed away after boiling.

- 6. Bleaching

Fibers are bleached with sodium hypochlorite or other bleaching powders, and any remaining scraps caught in the fibers are washed out. This additional step is a relatively new process added to meet the market demand for completely white paper, and was not necessary in the old days.

- 7. Beating

The whitened bark is placed in a beater and beaten with caustic starch for about an hour until the fiber tissues are sufficiently loose.

- 8. Forming balls

The bark fibers are formed into balls weighing about a kilogram each. This process is necessary to acknowledge the weight of the material when it is placed in the water tank. For every four fiber balls, six hundred milliliters of water is added along with fifteen liters of viscous liquid made from the roots of aibika. It is important to diffuse the fibers evenly in the liquid.

- 9. Papermaking

The fibers are scooped onto a flat sieving board. It is important to make the thickness even. In order to do this, the sieving board is gently and quickly shaken horizontally and vertically to shake off excessive water. Years of experience and much skill is needed to make all of the sheets the same thickness and quality. The sieved sheets are piled up carefully, pressed, and dried.

- 10. Cutting and pasting

Using a cutting machine, the sheets are cut to size. For a sliding door, forty-eight basic sized sheets of paper are pasted together. Papers are sorted and packaged according to the purpose of use.

Where to Buy & More Information

Iiyama Dento Sangyo Kaikan

-

Address

-

Tel.+81-269-62-4019

-

ClosedMondays (open if Monday is holiday and closed the next day), December 29 to January 3

-

Business Hours9am to 5pm

-

Website

See more Traditional Japanese paper

- Mino traditional Japanese paper

- Echizen traditional Japanese paper

- Tosa traditional Japanese paper

- Sekishu traditional Japanese paper

- Inshu traditional Japanese paper

- Awa traditional Japanese paper

- Ozu traditional Japanese paper

- Echu traditional Japanese paper

- Uchiyama Japanese paper