- Dolls, kokeshi

- Saitama

Iwatsuki doll Iwatsuki ningyo

A charming atmosphere created in a castle town

Delightful and exquisite culture

Description

What is Iwatsuki doll ?

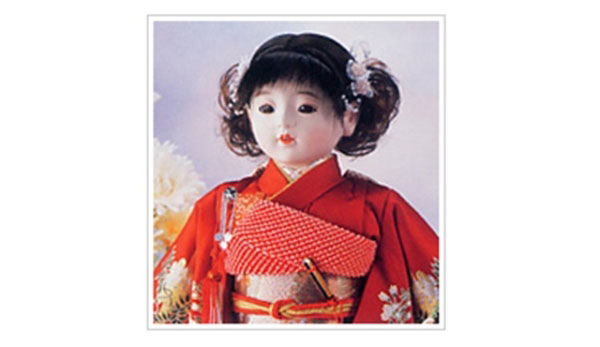

Iwatsuki doll (called Iwatsuki ningyo in Japanese) is a type of doll made in Iwatsuki ward, Saitama prefecture. This doll is known for its round face with big eyes, smooth and beautiful skin, and shiny human-like hair. The white skin comes from a white pigmented mixture of water, glue, and powdered calcium carbonate called gofun while the hair is made of raw silk. Soft silk resembling human hair is used and the hair is carefully tended to by a doll hair stylist.

Many paulownia wood products including chests and Japanese traditional sandals, (geta), have been produced in Iwatsuki ward and its surroundings for a long time. This ward is also a former castle town blessed with greenery, which had a good source of water that made a suitable environment for dollmaking. Iwatsuki ward prospered because of this craft. Even now, various Japanese dolls including Hina, Gotatsu, and Ukiyoe dolls are produced in this area.

History

The history of Iwatsuki dolls goes back to the Edo period (1603-1868). Many artisans visited Iwatsuki on their way to the construction of Nikko Toshogu Shrine (registered as a UNESCO World Heritage site) that started in 1634. Some of the artisans settled down in Iwatsuki and among them, there were artisans who were skillful at making dolls. Also, because Iwatsuki was blessed with a suitable environment for creating dolls, it became a "city of dolls" and a new technique using paulownia sawdust called tosogashira was established.

What greatly helped Iwatsuki become the "city of dolls" is the pastime of playing with dolls, hina asobi, being brought to Edo (ancient name of Tokyo) from Kyoto. This became such a popular activity in Edo at that time that even Kazuko TOKUGAWA (a granddaughter of the important military dictator Ieyasu TOKUGAWA, 1607-1678) brought dolls as gifts when she went to Kyoto's Imperial Court in 1626. The doll markets and merchants increased greatly, with the bustling activity depicted in an illustrated guide of pre-1868 Edo called Edo meisho zue. The dolls gradually became part of the Girls' Festival, also called Hina Festival, which is still held every March 3rd.

General Production Process

- 1. Doll head production

The base of the doll head is made with a kind of clay called toso that is poured into a mold and left to dry. The clay is made from a kneaded mixture of paulownia sawdust and wheat starch. It is also used for making the body of Japanese wooden dolls, called Kimekomi ningyo. The production process varies based on the kind of doll, but the process introduced here is for a costumed doll.

Once dried, the doll head base for the costumed doll has specialty eye parts fitted instead of them being drawn on. After the eyes are complete, it is time to make the facial features. After the base coat application of gofun, a white pigment, and glue, then the nose and lips are made with a sculpting technique called okiage using a small knife to work on details. Then, the second layer of coating and an overcoating is applied after which it is polished to give it a luster.

Facial expressions are also applied to the doll by drawing eyebrows, eyelashes, a tongue, teeth, blush, and lipstick. Finally, the hair is attached to the head and after styling, the head is complete.

The eyes may be painted on instead of using the eye parts, depending on the type of doll.

- 2. Production of hands and legs

The hands and legs are made using the same procedure as the head production, with paulownia sawdust clay.

A base coat of gofun, a white pigment, and glue is applied. A small knife is used for working on fine curves and details.

Finally, the hands and legs are polished. Nail polish may also be applied depending on the type of doll.

- 3. Production of the body

The production process for the body can also vary based on the type of doll. For a costumed doll, the body is made from warado, which is rice straw wrapped in Japanese traditional paper (washi). The warado has to be firmly attached to a foundation and a collar is also attached to the doll body to prepare the neck area. Then, the hands and legs are attached. Wire is used for the base of the hands and legs so that they can be bent into poses and straw is applied over the wire as the flesh. When the body is ready, garments are put on the doll. Finally, the pose of the doll is set and the process is complete.

The doll garments are all made the same way as human clothes are. Luxurious textiles like Nishijin brocade are used. The fabrics are lined with washi to make them firm and prevent the garments from losing their shape.

Unlike the costumed doll, straw is not used for wooden dolls. Instead, the base of the body is a mold made from paulownia sawdust clay, same as the head. Any protruding clay has to be removed with a bamboo spatula and when the base of the body is completely dry, any cracks that occurred during drying have to be smoothed out. Then, gofun is applied to the base when the surface is complete. Glue prevents damages on the surface and gofun makes the color of the fabric brighter. When the surface is dry, preparations are made for inserting a piece of fabric into grooves that have been carved with a line engraving chisel. Powdered flour made from cooked glutinous rice is kneaded and inserted into the grooves. Then the edges of the fabric are squeezed into the grooves using a spatula.

- 4. Making accessories

A specialty doll accessory craftsman makes small props like a wooden fan used in court, a ritual baton, a crown and a sword.

- 5. Assembling the doll

The doll is complete when the head and accessories are attached to the body. The garments and hair are adjusted to make the doll look perfect.

Where to Buy & More Information

Togyoku Co., Ltd. Iwatsuki Honten

-

Address

-

Tel.+81-48-756-1111

-

ClosedMay 6 - Sep 30: Mondays and Tuesdays / Oct 1-31: Mondays / Nov 1 - May 5: open everyday *extra holiday (May 8-10)

-

Business HoursMay 6 - Oct 31: 10am to 5pm / Nov 1 - May 5: 10am to 6pm

-

Website

See more Dolls, kokeshi

- Hakata doll

- Iwatsuki doll

- Kyo doll

- Miyagi kokeshi doll

- Edo-kimekomi doll

- Suruga-hina doll

- Edo-sekku doll

- Suruga doll accessories

- Edo Oshi-e Pictures on Embossed Fabric