- Dolls, kokeshi

- Shizuoka

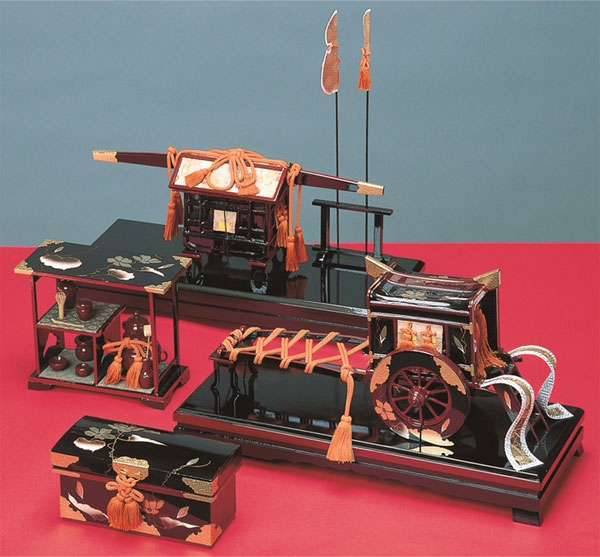

Suruga doll accessories Suruga hinagu

Luxurious lacquer decoration of landscapes

Exquisite craftsmanship that uses no nails

Description

What is Suruga doll accessories ?

Suruga Hinagu (Hina Doll accessories) are a traditional craft produced mainly in Shizuoka city, Kakegawa city and Yaizu city in Shizuoka prefecture. A distinctive feature of Suruga Hinagu is that every piece of furniture, such as chests of drawers, oblong chests and dressing tables, is manufactured using the same processes as life-size furniture into details. Using the traditional craft skills that have been developed in and around Shizuoka prefecture, including joinery, turnery, lacquering, Maki-e and metal fittings, the craftsmen lovingly create Suruga Hinagu. Each process of making Suruga Hinagu has created a specific category of local products in Shizuoka prefecture, such as Suruga Sashimono (joinery), Shizuoka Hikimono (turnery), Suruga Shikki (lacquer ware), and Suruga Maki-e (lacquer decoration). In particular, the manufacturing of Suruga Hinagu is said to have originated from Suruga Maki-e, as it is typically decorated with beautiful Maki-e of flowers, birds, mountains and water and arabesque patterns. Together with Suruga Hina Dolls, Suruga Hinagu has been adored through the centuries. Furthermore, the manufacturing of Suruga Hinagu was divided into several processes, from making the wooden base to finishing with maki-e. This established a system of a division of labor, which enabled mass production of hinagu, despite the fact that they are all made by hand. As a result, Suruga Hinagu now has a large share in the hinagu market in Japan.

History

In Suruga in the Muromachi Period (1392 - 1573), there was a custom to present papier-mâché hina dolls to young ladies. Later, in the period of the Tokugawa Shogunate (1603 - 1867), the second shogun Hidetada TOKUGAWA and the third shogun Iemitsu TOKUGAWA recruited craftsmen from all over Japan to construct Kunozan Toshogu Shrine and Sengen Shrine, respectively. These craftsmen remained in Suruga and spread their exquisite skills in all kinds of fields. In addition, there were various advantages in Suruga, for example, the warm and humid climate was suited for manufacturing lacquer ware. Thus, Suruga came to flourish as the center of handicraft production. They also succeeded in expanding their sales network, as they were located between Edo (Tokyo) and Kyoto, which were big cities in those days. This also helped Suruga expand its sales network. By the time of the Taisho Period (1912–26), wholesale associations were formed to strengthen the unity of the industry. In addition, cooperation began with the whole sellers in Tokyo to expand the sales of hinagu across Japan.

General Production Process

- 1. Preparing the wooden base Joinery is a method of assembling wooden articles without using any nails. It is an extremely delicate process, since a 0.01mm difference of thickness will make the assembly impossible. Wood turnery is a process in which roughly shaved wood is turned on a lathe and shaped with a blade into a round form, before it is formed to the final shape.

- 2. Lacquering The assembled wooden base is sanded down with sandpaper to adjust the shape, and urushi lacquer is applied by the lacquerer. There are three stages in the lacquering process: undercoating, intermediate coating and overcoating. Typically lacquer is applied and left to dry, then it is sanded down to smoothen the surface between each coating, and this process is repeated. Suruga-charcoal blocks, which are produced by burning tung tree, also known as the Japanese wood-oil tree, are often used for the sanding work as they are soft and suitable. In addition to the traditional urushi lacquer, a new type called "cashew lacquer" is also used for lacquering. Since the cashew lacquer has less odor and is less likely to cause skin rash compared to the traditional urushi, it is more suitable for hinagu, which children often touch with their hands.

- 3. Maki-e Maki-e lacquer decoration is applied by the maki-e artist. Maki-e is not directly painted onto the lacquered base. To create maki-e, first patterns are painted or stamped onto the base using urushi lacquer. Next, gold or silver powder is sprinkled on the patterns. The urushi lacquer works as a glue, making the gold/silver power stick to the patterns. The patterns typically used to decorate Suruga Hinagu are flowers, birds, mountains and water, and arabesque patterns. Since most maki-e is applied by hand, the level of the craftsman’s skills becomes apparent in this process. After the application of maki-e, the articles are left to dry and then polished with sheep skin to achieve a shiny finish.

- 4 Making metal fittings Metal fittings are made by the craftsmen for metal fittings. They are usually made from copper or copper alloy. The metal fittings for hinagu include the fittings to be attached to the edges of hinagu and the handles for drawers. The metal material is cut into a suitable size to work with, heated with charcoal fire, and then gradually cooled down. When it is cooled down completely, the surface is polished, and cut out to the shape of the pattern of the fittings which are marked on Japanese paper. The decorative patterns are engraved onto the fittings using a chisel, which is a tool used to engrave metal or carve stones.

- 5. Finishing The finishing work is carried out by the finisher. In this process the metal fittings or decorative threads made by the metal fittings' craftsman are attached to hinagu with rivets or glue. Although a lot of small parts are used in hinagu, the use of traditional skills makes it possible to attach them together. These old traditions can still be seen in a process like this, which form a basis for the finishers to work by hand today.

See more Dolls, kokeshi

- Hakata doll

- Iwatsuki doll

- Kyo doll

- Miyagi kokeshi doll

- Edo-kimekomi doll

- Suruga-hina doll

- Edo-sekku doll

- Suruga doll accessories

- Edo Oshi-e Pictures on Embossed Fabric