- Woven textiles

- Saitama

Chichibu-meisen silk Chichibu meisen

Traditional silk with wonderful bold patterns

Iridescent luster on both sides

Description

What is Chichibu-meisen silk ?

Chichibu-meisen silk is a textile produced in the city of Chichibu, Saitama prefecture.

It is a plain-woven textile with both sides dyed equally because the threads will be stencil dyed. Since the textile is double-sided, it can be washed and remade as a kimono numerous times. This durability resulted in the popularity of the textile among ordinary people. An assortment of silk is used. Raw, dupioni raw, floss, or spun silk made from waste cocoons and waste raw silk are used for Chichibu meisen. People are fond of this textile because they can use it casually and for a long time as it is woven with affordable materials.

Meisen with a pattern is called hogushi nassen because it is dyed after basting. The weaver has to remove the weft threads used for basting so the weaving method is called hogushi-ori (loosen and weave).

Chichibu meisen's iridescent luster makes it appealing. The warp (parallel) threads and the weft (perpendicular) threads are different colors which create a sheen. The more complementary the warp and weft thread colors, the better the effect.

History

The origin of Chichibu-meisen silk is said to go all the way back to the reign of Emperor Sujin (97-30 B.C.) when Chichibu Hikonomikoto, the regional administrator of Chichibu, originally brought the technology of sericulture and weaving to the area. Chichibu is surrounded by mountains so it was difficult to grow rice. Therefore, sericulture became successful in this area. Futo-ori was the textile woven for farmers' everyday clothing, becoming popular which led to it being called Oni-chichibu and worn by the common people. While it was popular among the everyday people, samurai warriors also valued the fine and durable characteristics of the textile.

Futo-ori became Chichibu-meisen and the combination of the tradition with new and improved technologies made the textile more popular. From the Meiji period (1868-1912) to the early Showa period (1926-1989) was the peak of popularity of Chichibu-meisen. Once hogushi nassen technology was developed and was patented in 1908, bold and elaborate designs became popular throughout Japan. People love Chichibu-meisen because the hiraori textile enables them to wear it on both sides and it can be remade many times as a kimono. After being thorougly used, Chichibu-meisen can also be recycled as children's diapers or cleaning cloths.

Production Process

- 1. Temporary weaving

The white warp threads have to be sorted first. The length and the threat count should be measured and counted before the warp threads are set in the loom. In the meantime, the weft threads have to be wound around tubes. When everything is prepared, the weft threads are pulled through the loom, making a provisional weaving. This temporary weaving prevents the threads from shrinking or becoming dislocated during the katazome (stencil dyeing) in the next step.

- 2. Printing

The woven white warp threads are spread over a printing stand as the printing process is done during this step. Stencil dyeing is done by a craftsman who uses one stencil at a time. A square frame with a pattern is placed over the warp threads. The craftsman gradually moves the pattern while carefully applying dye with a brush. When there are multiple colors, the craftsman dyes the threads as many times as the number of colors. The threads, instead of the woven textile, have to be dyed so that both sides of the woven textile are dyed equally. This printing technique is called nassen.

In order to refine and dye Chichibu-meisen, the textile must be immersed in a dye liquid called shinsen.

- 3. Steaming

The threads are put in a mushibako (steam box) and steamed to settle the dye. Steam boxes vary from assembled wooden boxes to tube-shaped ones.

- 4.Drying

The steamed threads are dried in a tumble dryer.

- 5. Rollback

Before weaving, the warp threads are rolled back while their condition is checked and adjusted.

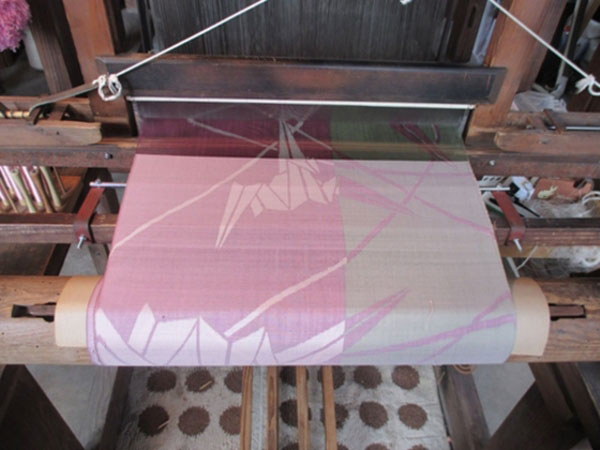

- 6. Weaving

The weft threads are sorted and the dyed warp threads are set in the loom. The woven weft threads are loosened and weaving starts. This method is called hogushi-ori (loosening and weaving) or hogushi nassen (loosening and printing) because the threads are woven as the weft threads are loosened.

Hand throwing shuttles or flying shuttles using a treadle are used to slide the weft threads across. Sometimes a shuttle loom, an auto-weaving machine with a shuttle, is also used. With a shuttle loom, the machine automatically replenishes the weft threads if they run out or get cut off and the machine can continue weaving.

An iridescent luster is created by the combination of the warp and the weft colors. The more complementary the warp and weft thread colors, the better the level of the finish. Great care is taken so that the warp threads are not cut or shifted to the wrong position.

Facility Information

Chichibu Meisenkan

-

Address

-

Tel.+81-494-21-2112

-

ClosedDecember 29 to January 3

-

Business Hours9am to 4pm

-

Website

Other Woven textiles

- Nishijin brocade

- Yuki tsumugi silk

- Kurume traditional resist-dyed textiles

- Ojiya chijimi textiles

- Hakata brocade

- Ushikubi tsumugi silk

- Chichibu-meisen silk

- Miyako ramie textile

- Shiozawa tsumugi silk

- Kumejima tsumugi silk

- Omi ramie cloth

- Ryukyu traditional resist-dyed textiles

- Kiryu brocade

- Murayama-oshima tsumugi silk

- Yumihama traditional resist-dyed textiles

- Chibana-hanaori textiles

- Hon-shiozawa silk

- Oitama tsumugi silk

- Ojiya tsumugi silk

- Yaeyama cotton cloth

- Yaeyama ramie cloth

- Honba oshima tsumugi silk

- Shinshu tsumugi silk

- Shuri brocade

- Tama brocade

- Yomitanzan-hanaori textiles

- Isesaki traditional resist-dyed textiles

- Hachio island silk

- Nibutani bark cloth

- Uetsu tilia bark cloth

- Awa-shijira cotton cloth

- Kijoka banana fiber cloth

- Tokamachi traditional resist-dyed textiles

- Tokamachi akashi chijimi textiles

- Yonaguni brocade

- Yuntanza minsa

- Flower pattern textiles

- Oku-Aizu Showa Karamushi Textiles