Copyright:Tokyo Convention&Visitors Bureau

Copyright:Tokyo Convention&Visitors Bureau

- Dolls, kokeshi

- Tokyo

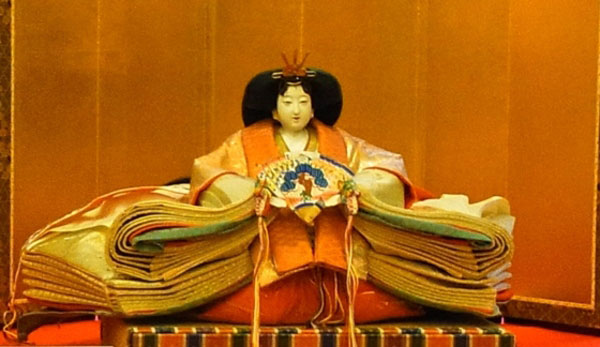

Edo-sekku doll Edo sekku ningyo

Craftsmen's skills and personalities are expressed in unique dolls

Freshness and beauty that appeal to people of all ages

Description

What is Edo-sekku doll ?

Edo Sekku Ningyo are dolls produced in 12 of the wards in Tokyo and four cities in Saitama Prefecture. They are costumed dolls, such as ichimatsu ningyo (play dolls), gosho ningyo (palace dolls) and fuzoku ningyo (dolls in period costumes), as well as decorative armor. They are usually displayed during the Doll's Festival or the Boy's Festival. In the late Edo Period (1603 - 1868), there was a market selling hina dolls and dolls in samurai armor in Nihonbashi Jikkendana (Tokyo), which was counted as one of the most popular sites in Edo. Ordinary people of that time were becoming wealthy enough to hold a luxurious and grand celebration for their child's first annual boys' or girls' festival to pray for their health and prosperous future. Edo Sekku Ningyo were originally displayed outdoors, but later displayed indoors; therefore they became distinctively small. These Edo-style dolls have a natural feel, are realistic and delicately crafted. The armor is made so realistic and accurately detailed that some of them could be mistaken for the real thing. The use of carefully selected natural materials, including leather, silk threads, wood, paper, steel and copper, and traditional production processes makes it possible to produce simple but elegant armor, the pride of samurai in the Edo Period, even today.

History

Manufacturing of dolls started in Edo, current Tokyo, in the early days of the Edo Period (1603 - 1838), under the influence of doll making in Kyoto. However, it was not until the Horeki Era (1751 to 1763), about 250 years ago, that a unique Edo style was established. In 1761, during the reign of the 10th shogun Ieharu TOKUGAWA, a doll-making artisan from Kyoto who invented "Jirozaemon-bina" (Hina dolls with round faces) came down to Edo to open a doll shop. Since then doll making became widely spread across Edo. One of the main dolls produced around 1716 to 1736 were "Kyoho-bina" dolls, which were relatively large in size and sumptuous and opulent. They were considered to be "luxury items" and even the government was avoiding them. On the other hand, Jirozaemon-bina were well-received since their facial expressions and structure were more accessible to ordinary people, and thus they became a part of the Edo culture. The heavy influence of the style of Jirozaemon dolls can be seen in the modern Edo Sekku Ningyo, which are still cherished today.

General Production Process

- 1. Making the head The head is made with a clay called toso, made by kneading wheat starch paste and paulownia wood saw dust, and is pushed into a mold. Alternatively, it can be made by bisque-baking dolomite clay, which is a traditional material for making the face and other skin parts of Hina dolls, or by carving a piece of wood. The mold for the head is prepared in advance and consists of two parts: the front (face side) and the back side of the head. Oil is applied inside the mold, and then the fine toso clay is pressed into it while leaving the core of the head hollow. After being fully dried, the head is carefully filed to shape.

- 2. Applying whitewash For the head made from toso or carved wood, a base coating is applied and left to dry. Next gofun, whitewash made from seashells, is painted on the head, and the mouth and nose are formed with gofun at this stage, too. They are then shaved with a small knife to create the desired shape. Following this, the second coat is applied using thicker gofun, and the head is shaped and left to dry. Then a damp cloth is used to remove any excess gofun. Next the facial expression is created by carving the face. Using a brush, an overcoating gofun is meticulously and evenly applied carefully and repeatedly for about ten times.

- 3. Painting the face When glass eyes are used, openings for the eyes are cut using a small knife. The eyebrows and hairline are painted using fine-tipped brushes with Japanese ink, and then lips are painted in red.

- 4. Attaching hair First, grooves are cut in the parts where the hair will be fixed using a small knife. The tips of black dyed silk threads are aligned and trimmed off before applying glue. Then the hairs are fixed into the prepared grooves using a prick punch.

- 5. Making the body The toso that was used for making the head is mixed with wheat starch paste, and pressed into the the front and back body molds, and then the two halves of the molds are put together to form one piece. The pair of molds is held down and the front mold is removed to scrape off any burrs before removing the back mold. Then, the back mold is slowly removed.

- 6. Applying gofun to the body Gofun is dissolved with animal glue, an organic protein produced from animal skins or bones, and applied to the body. Since this process helps to harden the paste used for the body and also prevents the body losing its shape, it has to be applied evenly and smoothly. When the gofun is completely dry, grooves are carefully cut with a small knife to make it ready to tuck in the costume.

See more Dolls, kokeshi

- Hakata doll

- Iwatsuki doll

- Kyo doll

- Miyagi kokeshi doll

- Edo-kimekomi doll

- Suruga-hina doll

- Edo-sekku doll

- Suruga doll accessories

- Edo Oshi-e Pictures on Embossed Fabric

See items made in Tokyo

- Edo kiriko cut glass

- Edo wood joinery

- Edo glass

- Murayama-oshima tsumugi silk

- Tokyo silverware

- Edo patterned paper

- Tokyo fine-patterned dyeing

- Edo bamboo fishing rods

- Tama brocade

- Hachio island silk

- Woodblock prints

- Tokyo textiles

- Edo-sekku doll

- Edo Hyogu (Art Mountings)

- Edo Oshi-e Pictures on Embossed Fabric

- Edo tortoise shell crafts

- Tokyo Honzome Chusen

- Tokyo Koto (Japanese Harp)

- Tokyo Plain Dyeing

- Tokyo Shamisen

- Tokyo antimony craft