- Semiprecious stone craftwork

- Fukui

Wakasa agate craft Wakasa meno zaiku

One of the roots of Japanese craftsmanship

As vivid and red as a blazing fire

Description

What is Wakasa agate craft ?

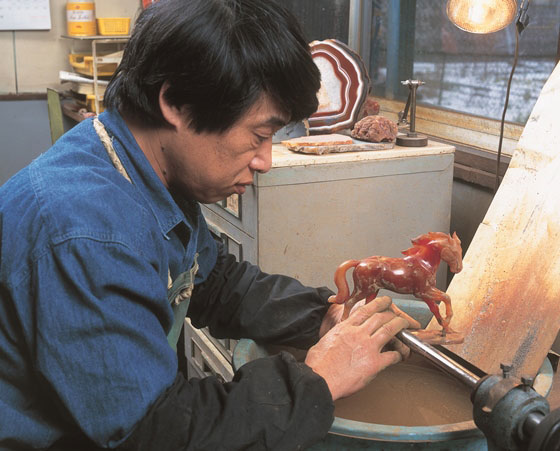

Wakasa Agate Craft (Wakasa Meno Zaiku in Japanese) is agate craftwork produced around the city of Obama, Fukui prefecture. Agate has been appreciated from olden times as one of the seven treasures that decorated the sublime Buddhist paradise mentioned in the Sutra of Immeasurable Life. Wakasa Agate Craft is also known as the origin of gemstone crafts in Japan. It is distinguished by its translucent flame-bright red color which is produced from a distinctive heating process using iron. The deep brownish red color refines the features of the craft. They have a wide product range from daily utensils such as soup bowls and chopstick rests to ornaments of roosters and carp which are often given as gifts.

History

The origin of Wakasa Agate Craft dates back to approximately 270 years ago. Sometime between 1716 and 1735, Kichibei TAKAYAMA returned to his hometown in Wakasa after completing his apprenticeship at an optician's store in Naniwa (current Osaka). Based on the skills he had gained, he started making agate beads, which is considered to be the beginning of the craft. Its turning point was in the early days of the Meiji period (1868-1912), where the craft evolved to the current form of intricate work pieces we know today. Heisuke NAKAGAWA, a Wakasa Agate Craft artisan had ambitions to innovate the simple beads craft into an enriched craft. His effort to enhance the craft made the current form of engraved crafts such as the carps and roosters. The artisan skills developed to the point where their works were viewed as works of aesthetic value and were exhibited across Japan as well as overseas. In 1976, Wakasa Agate Craft was registered as a Japanese Traditional Craft.

General Production Process

- 1. Gemstones

Wakasa Agate Craft is made of agate gemstones. Around the Meiji period (1868-1912) when the agate craft was starting to develop, agates from Hokkaido were used. However, due to the exhaustion of natural resources, agate from Brazil is often used nowadays.

- 2. Inspection

Only the suitable quality agates are used for agate craft, which requires careful sorting and inspection. The form of the craft will be decided depending on the patterns and colors of the agate gemstones. Basically, solid agate rocks are used for sculptures, and hollow agates are cut and used for accessories.

- 3. Rough cutting

According to the design of a piece, the gemstone is roughly cut down to size with a special bow type cutting machine. As the machine plate does not have a blade, the artisan has to ensure a constant supply of slurry made of ground sand and water during the cutting.

- 4. Oxidizing

The rough piece is left outside until it has naturally oxidized, which helps to bring out the vivid red color when heated.

- 5. Heating

Heating is a distinctive process of Wakasa Agate Craft. The gemstone is placed in ashes and heated with charcoal. This is repeatedly processed to bring out the natural reddish color. Heating is a highly-skilled task, as overheating may shatter the stone, while an insufficient temperature heating will cause low or no degree of translucence to the piece. Today, it is also common to heat gemstones at about 300ºC in an electric oven for several days.

- 6. Cutting

After heating, the rough design outline is drawn on the stone with graphite and the unnecessary parts are cut off to prepare the stone for carving.

- 7. Chipping

A nail like tool called tetsuya is tapped with a small mallet to shape the stone. The stone is fixed between the artisan's knees during this shaping process.

- 8. Shaping

After the chipping, the detailed parts are to be shaped. The stone is shaped by polishing with rough sand in the beginning and progressively using finer grades of sand.

- 9. Polishing

The final process is mud-polishing with fine ground sand, followed by polishing with polishing powder to give a very smooth shiny surface, which enhances the beauty of the agate. Polishing may sound simple, but it could take more than a month for intricate agate pieces. It requires the artisan's full attention, and such careful polishing is indispensable to bring out the great depth and translucent hue distinctive to Wakasa Agate Craft.

Where to Buy & More Information

Fukui Ceramics Center

-

Address

-

Tel.+81-776-41-3611

-

ClosedAround the New Year

-

Business Hours9am to 5pm

-

Website