- Ceramic

- Fukui

Echizen ware Echizen yaki

One of Japan's Six Ancient Kilns

Simple, warm and natural beauty

Description

What is Echizen ware ?

Echizen ware (called Echizen yaki in Japanese) is a type of pottery produced in the town of Echizen, Fukui prefecture. This traditional handicraft comes from one of the Six Ancient Kilns of Japan which along with Bizen, Tamba, Tokoname, Seto, and Shigaraki, are the most outstanding Japanese kilns with traditions that remain even today. These ancient kilns began production from the Heian period (794-1185) to the Kamakura period (1185-1333).

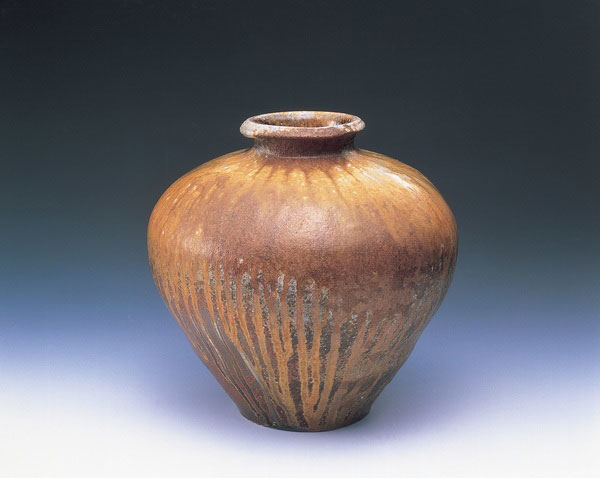

Echizen ware is notable for being fired without the use of enamel and pieces are often not decorated either, resulting in a simple texture. One of the appeals of Echizen ware is its natural glaze that comes from firewood ash covering and dissolving into the pieces as they are baked at a high temperature. Therefore the pieces are a form of earthenware between pottery and porcelain, also called yakishime or semi-porcelain. Production has mainly centered around items used in everyday life, such as pots, jars, drinking containers, and tea utensils, as these dark reddish-brown vessels are thoroughly densified, strong and leakproof.

History

Echizen ware has an ancient history going back around 850 years to the late Heian period. Today, while there are productions using various new techniques, traditional and simple items remain the focus. Over time items for the kitchen came to be produced, including jars for water and grain storage, sake bottles for preserving alcohol and oil, as well as mortars.

In the latter part of the Muromachi period (1336-1573), cargo ships sailing on the Sea of Japan started transporting on a route that went as far north as Hokkaido all the way down to Tottori prefecture in the southwest. These ships carried merchandise from Hokkaido to Osaka, passing across the Sea of Japan and heading south through the Seto Inland Sea. Thus, Echizen ware was able to develop and spread throughout Japan. However, moving into the Meiji period (1868-1912), Japan modernized and the demand for jars and pots suddenly went down. Other ancient kilns had started to bake high-class items such as tea utensils during the Edo period (1603-1868), but Echizen ware was consistently producing generic vessels, exacerbating its decline. At last, thanks to postwar era research into ancient kiln remains, the historical value of Echizen ware was reexamined. The craft was revitalized when the Echizen Ceramics Village was established in 1970, which triggered a surge in the number of potteries and attracted a large number of tourists to the Echizen area.

General Production Process

- 1. Base production

In order to produce Echizen ware, it is necessary to excavate clay first. Clays that are unique to this region are collected and blended, like akabeto, aoneba and takodo. Elutriation* is conducted in order to remove impurities and ensure that the grain of the clay is even. Then, the clay is laid down for a while and thickened to enable casting, after which chrysanthemum kneading is done. Because the kneading or spiral wedging involves both large rough massaging and smaller careful massaging, the form of the clay ends up resembling a chrysanthemum while it is being kneaded which is why it is called "chrysanthemum kneading".

Once the clay has been produced, it is at last time to do casting. The casting method varies depending on the form of the vessel. For items that are rectangular or complex in form, a mixture of clay and water is poured into a plaster mold while circular pieces are formed with a lathe. The base clay is produced on top of a wooden stand that has been firmly fixed in place.

*Elutriation is a process that removes silica grains from ground porcelain stone placed inside a mixing tank, eliminates iron, and dehydrates by applying pressure.

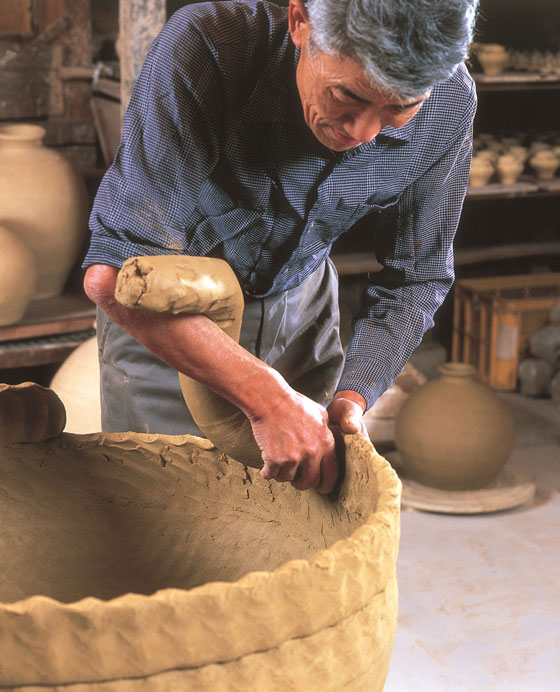

- 2. Casting

String-shaped yorido clay about five to ten centimeters thick and forty centimeters long is held in the right hand of the arisan and wrapped around the base clay while being twisted. The left hand supports the force with which the right hand wraps the yorido clay while constantly evening out the height of the clay. This step is repeated for the second level as for the first level. The method of piling up many levels while twisting string-shaped clay is known as wazumi casting.

- 3. Smoothing

After piling the clay in a cylindrical shape, the surface is smoothed with a soldering iron. Even the outer seams that revolve the circumference of the item are rubbed from top to bottom with the iron. Then, the interior is stretched into a fan shape.

- 4. Drying and repeating

Once the base of the piece has been formed, it is dried. Then, it is adjusted so that it can withstand the weight of the top parts. Finally, production steps two and three are repeated until the entire item is finished.

- 5. Mouth production

The mouth of the piece is produced. The vessel is covered with a cotton cloth soaked in water, and smoothed out while pressed down with both hands. Various mouth shapes can be produced depending on how the fingers are used.

Lastly, the item is placed inside a kiln and baked at high temperature. The temperature for baking is 1200 to 1300℃ (about 2192 to 2372℉).

Where to Buy & More Information

Fukui Ceramics Center

-

Address

-

Tel.+81-778-32-2174

-

ClosedMondays and the next day of holiday (except Saturday, Sunday and holiday), December 28 to January 4

-

Business Hours9am to 5pm

-

Website

See more Ceramic

- Imari ware/Arita ware

- Hasami ware

- Kutani ware

- Mashiko ware

- Shigaraki ware

- Bizen ware

- Hagi ware

- Koishiwara ware

- Mino ware

- Tobe ware

- Tokoname ware

- Karatsu ware

- Kasama ware

- Satsuma ware

- Iga ware

- Mikawachi ware

- Agano ware

- Otani ware

- Obori-soma ware

- Tsuboya ware

- Aizu-hongo ware

- Shodai ware

- Echizen ware

- Akazu ware

- Tamba-tachikui ware

- Yokkaichi-banko ware

- Izushi ware

- Kyo ware/Kiyomizu ware

- Iwami ware

- Amakusa ceramics

- Seto-sometsuke ware

- Sanshu Onigawara Crafts