Photo:Shimane Perfecture

Photo:Shimane Perfecture

- Writing tools

- Shimane

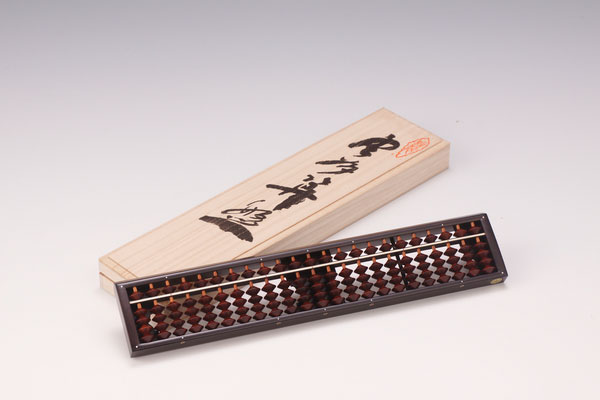

Unshu abacus Unshu soroban

180 handcrafted steps are needed

to create one superb piece

Description

What is Unshu abacus ?

Unshu abacuses (called Unshu soroban in Japanese) are produced in the town of Okuizumo, Shimane prefecture. Japanese abacuses are traditional tools that use columns lined with beads that are quickly moved with the fingers to do calculations. They are still used today to teach children arithmetics and to help prevent dementia for elderly people.

Traditional handicraft methods are used to carefully produce the abacuses with all natural materials. The beads are produced out of witch hazel from Kagoshima prefecture or birches that mainly come from Tochigi, Gunma, Saitama, or Iwate prefecture. The frame is crafted with ebony, black ebony, or special reinforced plywood. The rods are crafted with processed bamboo or soot colored bamboo.

Unshu abacuses are distinct for having high quality beads that seem to stick to the fingers during use. With quick finger movements, the beads can be moved very smoothly and make a clear sound as they strike each other. This craft is respected for its finest qualities for each abacus with the shape of beads, uniform hole sizes, and accurate intervals between the beads and axles.

There are three types of abacuses: portable, academic, and wholesaler use, which all vary in length and size. Unshu abacuses can be used for many years with minimal care like a quick wipe with a soft dry cloth after use. Like most wooden items, abacuses are not suitable for high temperatures and humid environments and require storage in a cool location, out of direct sunlight. As it is a delicate product, an abacus with serious water damage might not be repairable.

History

Photo:Shimane Perfecture

Photo:Shimane Perfecture

In 1832, Kichigoro MURAKAMI (1787-1876) a carpenter living in the former town of Nita (now Okuizumo) used Hiroshima abacuses as a model to make the first Unshu abacus from oak, Japanese apricot, and smoke stained bamboo found in the region. This area is also known as a production district of tamahagane, which is the steel made from iron sand or black sand that is used to produce sword blades. The Nita district was blessed with suitable wood materials and quality steel tools, which helped the abacus industry to flourish. The production volume increased after the production process was displayed to the public. After World War II, the manufacturing process was further mechanized and led to modern mass production.

Today, the role of the abacus in society has been replaced by computers and electronic calculators. However, the humble abacus is still used as a tool to teach children mathematics and exercise the mental capacities of the elderly.

It is said that the hand movements from the abacus stimulate the central nervous system, encouraging different parts of the brain. It is also considered helpful for maintaining and improving mental comprehension. Lately, there has been a reevaluation of the abacus and it is still an active part of Japanese culture.

Production Process

Photo:Shimane Perfecture

Photo:Shimane Perfecture

- 1. Beads production

The suitable timber for the abacus beads are chosen and thoroughly dried in preparation for shaping. The texture of timber for the beads should have both firmness and a gentle touch for use with fingers. Timber used for beads is mainly ebony, rosewood, or Japanese box. High craftmanship is needed to cut the hard timber, carve the wood into specially shaped abacus beads, and polish them.

To start the production, a machine is used to slice the seasoned timber. Then careful shaping is done to carve a final spherical shape out of the rough piece cut out of the wood.

- 2. Making rods

The rods of the basic popular abacus are mainly made from Japanese timber bamboo, while higher grade abacuses use smoke stained bamboo. The bamboo is cut to length, further cut into smaller pieces, and shaped to the beads. A fine polish is given to the beads for ensuring smooth movements.

- 3. Frame assembling

The abacus frame is made from either imported hard ebony or reinforced plywood. The wood is roughly cut to the length and size. Then the roughly shaped pieces are shaped further.

- 4. Strengthening the frame

The upper and lower frame of an abacus are separated by a distinctive wooden crossbeam called a hari, which supports and strengthens the rods and frame structure. First, holes are drilled in the crossbeam and then both sides are planed and finely polished. Then, grooves are routed on both sides of the crossbeam in the preparation for filling with a distinctive white celluloid.

- 5. Upper and lower frames

Holes are drilled on the upper and lower frames for the bead rods. All the parts including the sides are planed to a beautiful finish. Then the frame is strengthened by drilling holes to fit a thicker supportive axle and back rods. After preparing the backboards, the routing grooves are made to mount the backboards and mortises are drilled on the beams. Then the grooves are filled with white celluloid.

The process moves onto the tenon joints for the assembling of frames. First, all the pieces of the abacus are temporarily assembled and any necessary adjustments are made before the final assembly. Then, the temporary assembled frame is disassembled. The beads are slid onto the rods and all the components are assembled again. The Unshu abacus uses a technique of drilling the joint holes at strategic locations and inserting aluminum wire pins to further strengthen the integrity of the frame. The completed frame is given a final light sanding and polishing. Unshu abacuses are renowned not only for their practical and durable construction, but also for the natural beauty of their wood grain.

Facility Information

Shimane Bussan Kankokan

Photo:Shimane Perfecture

Photo:Shimane Perfecture

-

Address

-

Tel.+81-852-22-5758

-

ClosedAround the New Year

-

Business Hours9am to 6pm

-

Website

Other Writing tools

- Kumano brushes

- Ogatsu inkstone

- Akama inkstone

- Unshu abacus

- Banshu abacus

- Nara brushes

- Suzuka inksticks

- Toyohashi brushes

- Kawajiri brushes

- Nara Ink