Photo:Ishikawa Prefecture Tourism League

Photo:Ishikawa Prefecture Tourism League

- Industrial art materials and tools

- Ishikawa

Kanazawa gold leaf Kanazawa haku

Devoted to transmuting traditional materials

into dazzling beauty

Description

What is Kanazawa gold leaf ?

The word haku means metal leaf and Kanazawa haku is gold leaf produced in and around the city of Kanazawa, Ishikawa prefecture. This craft possesses the dazzling and elegant radiance of gold even after being worked on by craftsmen. A small piece of gold alloy, no bigger than 23 mm (0.9 in) in diameter, can be repeatedly hammered and thinned to cover one traditional tatami mat (about 1.6 ㎡) without losing its brilliance. It takes many years of devoted practice for artisans to learn how to produce such high quality and splendid gold leaf.

Kanazawa gold leaf is used in large quantities on historic buildings like the Nikko Toshogu (a shrine registered as a UNESCO World Heritage site), and often applied to the traditional crafts of the region, such as Japanese lacquer utensils, Buddhist altars, fittings, textiles, and Kutani ware. Today, Kanazawa gold leaf is widely used for modern crafts, interior goods, fashion items, and other miscellaneous goods.

In the past, it was difficult to engage in gold leaf manufacturing as an occupation because of restrictions imposed by the shogunate (Japanese military government). Despite the limitations, production persisted as the climate of Kanazawa, with its rain, snow, and high quality water, are ideal for stretching the gold leaf well and delivering a lustrous finish.

History

Photo: Ishikawa Prefecture Tourism League

Photo: Ishikawa Prefecture Tourism League

The origin of the metal leaf production industry is believed to have been during the early Heian period (794-1185) when the Ninomaru palace of Kanazawa castle was burnt down in 1808. Reconstruction required a large amount of gold leaf, however the shogunate at this time allowed the production of gold leaf only in Edo (ancient name of Tokyo) and Kyoto and prohibited it everywhere else. Because of these strict rules, Kanazawa metal leaf production occurred in secret with the cover story that gold or silver goods bought in Edo or Kyoto were being repaired or that copper and brass foil was being produced instead. While in 1817, gold leaf was used by Kanazawa based craftsmen to decorate Takezawa Palace, which was built on the grounds of Kenroku-en (a famous traditional garden located in Kanazawa), the use of gold leaf produced in Edo was required until the year 1845.

From 1864, the production of Kanazawa gold leaf was allowed but only for the domain's personal use in 1864. Still, the craft was able to develop and flourish with the repeal of complete prohibition on producing gold leaf.

Finally, it became possible to send the craft to markets all over Japan during the Meiji period (1868-1912) after Edo gold leaf stopped being produced.

During World War I, the production process of Kanazawa gold leaf became increasingly machinery-based in order to keep up with global demand. Then, restrictions on the use of metals because of World War II had a devastating effect on the metal leaf industry. However, the craft was able to recover greatly during the postwar period as production was restored and the product range expanded.

Production Process

Photo:Kanazawa city

Photo:Kanazawa city

- 1. Gold alloy

Gold leaf is not made by simply beating and extending pure gold metal. First, a mixture of pure gold with a minute quantity of silver and copper is made. The mixture is placed in a hearth bowl and heated to about 1300℃ (2372℉) and stirred with a carbon rod. Then, the resulting alloy is poured into a metal crucible to cool.

- 2. Expanding the gold alloy

The gold alloy is expanded to a belt-like shape called nobe, which is cut with a cutting tool into small square pieces about 6 cm big.

- 3. Preparation with paper

First, the gold alloy squares are placed on a square piece of traditional Japanese paper sized 12.6 ㎠ and layered under approximately two hundred sheets of paper. Then, about thirty sheets of oil blotting paper are placed above and below the gold before everything is covered with a leather bag and securely fastened with leather.

- 4. Beating the gold alloy

The thin strips of gold alloy must slowly be beaten until size 12.6 ㎠. Then, a stack of about two hundred papers that are size 16.8 ㎠ are inserted between blotting papers.

Then, the gold squares are extended until size 18.3 ㎠. Next, the gold is transferred onto square paper that is 21.6 cm on all sides and stretched before being trimmed with scissors.

Afterward, the gold is transferred onto another kind of paper and further beaten to be processed into uchi agari zumi sheets.

- 5. Cutting to size

About thirty sheets of uchi agari zumi are piled up, folded using a 20.1㎠ pattern, and cut along the folds with a tailor's knife. The cut sheet is a final sheet of gold metal. The sheets are folded into three, packed in a box and delivered to the leaf makers. All of the processes until now have been performed by the artisans and the next steps are done by gold leaf artists.

- 6. Inspecting the paper

True gold leaf requires further beating of the final gold sheets. The quality of the specially processed leaf beating paper is important as it affects the spreadability and luster of the final product.

- 7. Insertion into the beating paper

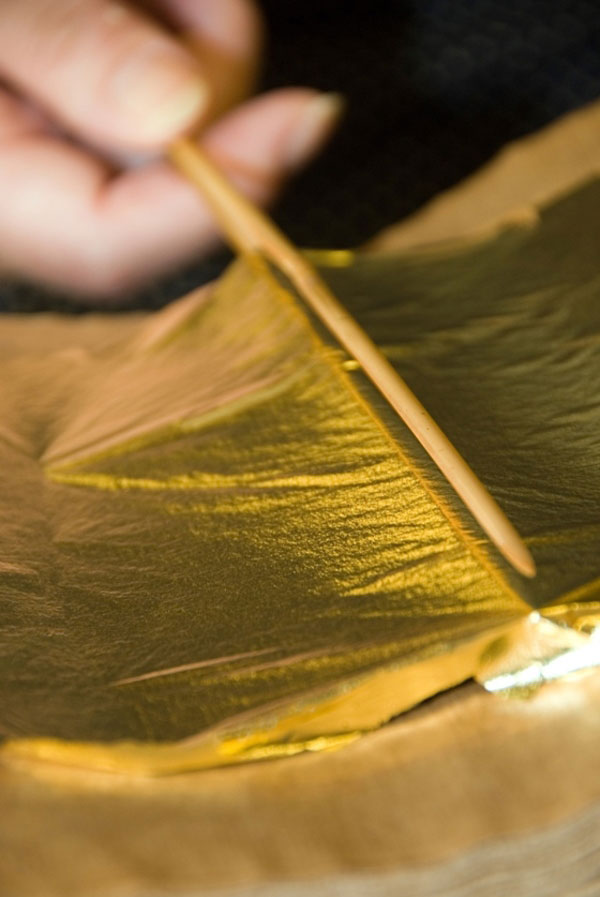

During this step, gold sheets measuring about 3/1000 mm becomes a leaf as thin as about 1/10,000 or 2/10,000 mm. A 21㎠ sheet of gold is cut with chopsticks into eleven or twelve small pieces called koma. The pieces are inserted between stacked paper sheets, where they are left temporarily before being transferred to beating paper.

- 8. Beating

Koma sheets are piled up and megami paper is added to the top and bottom of the stack. Then, white covers are added to the top and bottom, and leather is applied and tightened by winding and pasting.

The whole top and bottom of the stack are covered by bag leather and held firmly by leather. The stack is mechanically beaten at a constant seven hundred strokes per minute, ensuring rapid finishing and uniform product quality.

- 9. Transferring and grading The leaf extended by machine is transferred and beaten to the size of the main paper. The finished leaf is then transferred to a stack of a hundred papers for the final assessment. The quality is graded and the finished leaf is temporarily stored in a box until being cut to size.

- 10. Transfer of leaves

The leaf kept in the book are cut to one of four sizes, 10.9 ㎠, 12.7 ㎠, 15.8 ㎠, or 21.2 ㎠. A cutting frame is used to cut a gold leaf placed on leather board while shifting up and down. The trimmed gold leaf are placed onto specialized Japanese paper called kiri gami, which means cut paper.

Facility Information

Kanazawa Yasue Gold Leaf Museum

Photo:Ishikawa Prefecture Tourism League

Photo:Ishikawa Prefecture Tourism League

-

Address

-

Tel.+81-76-251-8950

-

ClosedDecember 30 to January 1

-

Business Hours9:30am to 5pm

-

Website