Photo:Ishikawa Prefecture Tourism League

Photo:Ishikawa Prefecture Tourism League

- Household Buddhist altars

- Ishikawa

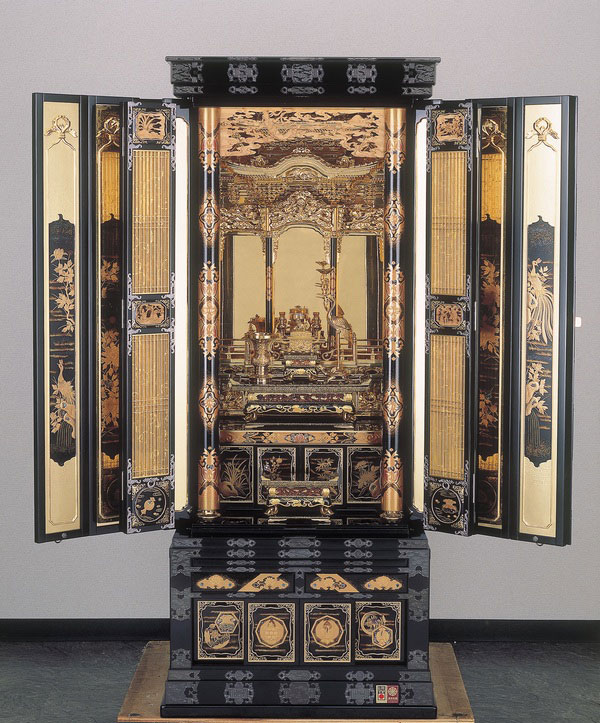

Kanazawa Buddhist altar Kanazawa butsudan

Elaborate gold lacquer and gold leaves decorations

A luxury delivered by the culture of Kaga and traditional techniques

Description

What is Kanazawa Buddhist altar ?

Kanazawa Buddhist Altars (called Kanazawa Butsudan in Japanese) are made in Kanazawa, Ishikawa prefecture. In the past, Ishikawa was an incredibly wealthy province called Kaga. This wealth was reflected in the rich Kaga culture of luxurious crafts still produced to this day. Kanazawa Buddhist Altars gained national recognition as a traditional craft in 1976 and has a splendid style, rich with artistic maki-e techniques. All the pieces of the Buddhist altar, such as front pillars, center pillars and back of the door panel, are adorned with beautiful maki-e decorations using techniques such as migaki maki-e and taka maki-e. Other unique features of this craft include a curved beam called uneri nageshi under the transom, a paper door mounted on a rotating shaft, rounded ebony wood sculptures, and coral or ivory inlay. As Kanazawa is renowned as the main producer of gold leaf within Japan, they are capable of procuring high quality gold leaf easily. This is why they are able to use a sufficient amount of good quality gold leaf in Kanazawa Buddhist Altars.

History

The history of Kanazawa Buddhist Altars is thought to date back to the late 17th century, when the lord of the Kaga domain (Ishikawa prefecture), Toshitsune MAEDA, gathered a number of artisans from Kyoto and Osaka and established specialized workshops to produce various artwork and crafts in Kaga. There were twenty three workshop categories, including maki-e, lacquer work, metalwork, paintings, inlay, and sword making. The produced pieces were given to the shogunate, noble family and temples, as gifts and donations. The workshops produced many talented artisans, and many were subsequently involved in Buddhist altar production using the techniques developed at the workshops. The Kaga domain had strong ties with Buddhism dating back to 1471, when a prominent priest of the Jodo Shinshu sect, Rennyo, established a temple in Awara, Fukui prefecture, propelling the Jodo Shinshu sect of Buddhism into widespread popularity throughout the whole Hokuriku region (including Ishikawa prefecture). After the religious reforms of the Tokugawa shogunate* during the Edo period (1603-1868), many households set up Buddhist altars at their homes. Kaga domain had an advantage for altar proliferation compared to other areas.

*The Tokugawa shogunate is the feudal military government that was in power during the entire Edo period.

General Production Process

Photo:Kanazawa city

Photo:Kanazawa city

- 1. Wooden base

This process includes making the exterior of a Buddhist altar, stand where the Buddha statue is placed, main pillars, drawers, and the ceiling. Kanazawa Buddhist Altars mainly use Japanese cypress and gingko because of their high durability. After drying the wood completely, it is cut into sizes depending on the use, then cut with a saw to the proper thickness and shapes. Tenons and mortises are also made at this stage.

- 2. Roof

Kuden, the roof above the inner sanctuary where the Buddha statue is enshrined, is made of Korean pine, Japanese cedar or gingko. All of the elaborate, small parts are handmade and carefully assembled. Comprised of over a thousand pieces, a single altar involves patient and meticulous work by the artisan.

- 3. Wood sculpture and gilding

Hakubori is a wood decor carving that is decorated with lacquer and gold leaf. Mainly, Korean pine is used for decor carving. After being dried completely, the wood is cut out based on the design, and the pattern is drawn on the cut wood. The pattern is roughly carved, followed by semi-fine carving, and finish carving with different kinds of chisels and knives. The sculptured pieces are then lacquered.

- 4. Wood sculpture

The upper, middle, and lower wooden skirting of the sliding screen door are carved and are not lacquered or decorated with gold leaf to make good use of the wood grain. The natural effects of wood are maximized with hardwood such as boxwood and mulberry tree. Once the wood is dried completely, flowers, birds or heavenly maidens are drawn and carved out. Sculptured pieces are assembled after being polished with scouring rush.

- 5. Ornamental fine metal

Various patterns are engraved in copper, brass, or sometimes silver for a high end altar. After being traced on the base metal with a needle, beautiful patterns are engraved with a chisel. Then, the engraved fine metal is immersed in nitric acid and rinsed off with water. After drying completely, the metal is finished in gold plating.

- 6. Lacquering

The wooden base, inner sanctuary, and carved wood are lacquered. After any scratches or knots on the wood base have been shaved, a base coat is applied and levelled with sandpaper to smooth the surface. Lacquering involves a process of coating the surface with a lacquer made of polishing powder and base layer coating, whetting to smooth the surface, painting with lacquer, drying, and repeating multiple times.

- 7. Maki-e

Maki-e is a technique of drawing exquisite designs on the lacquer painted surface and sprinkling gold or silver powder on the designs. This technique is used on the front and middle pillars and back of the door panel. The design is traced onto the surface with a traditional paper called Mino washi and lacquer. Then lacquer is applied several times to raise the surface, the design is drawn with color lacquer, and gold or silver powder is sprinkled. For togidashi maki-e, more lacquer is applied and then scraped off to show the design beneath.

- 8. Roiro

Roiro is burnishing a lacquered surface or maki-e to add a smooth, glossy finish. After drying, the surface painted with black lacquer is smoothed with charcoal, rubbed with a mixture of polishing powder and canola oil to remove any scratches, and burnished with crushed deer antler to add luster.

- 9. Gilding

Gilding is a technique of carefully layering sheets of gold leaf one by one over a surface that has been painted with raw lacquer. The gold leaf is gently pushed down with floss silk which makes the edges of ultra thin gold leaf align together to be seamless.

- 10. Assembly

Assembly is the final process of the Buddhist altar production. All the parts, including the wooden base, inner sanctuary, wood sculptures, and ornamental fine metal, are assembled to complete one altar.

Where to Buy & More Information

Ishikawa Prefectural Museum of Traditional Arts and Crafts

Photo:Ishikawa Prefecture Tourism League

Photo:Ishikawa Prefecture Tourism League

-

Address

-

Tel.+81-76-262-2020

-

ClosedApril to November: 3rd Thursday of the month / December to March: Thursdays / around the New Year

-

Business Hours9am to 5pm

-

Access1-1 Kenroku-machi, Kanazawa-shi, Ishikawa-ken

-

Website

See more Household Buddhist altars

- Osaka Buddhist altar

- Hikone Buddhist altar

- Iiyama Buddhist altar

- Nagoya Buddhist altar

- Kanazawa Buddhist altar

- Kawanabe Buddhist altar

- Kyo Buddhist altar

- Hiroshima Buddhist altar

- Mikawa Buddhist altar

- Kyo Buddhist altar equipment

- Nanao Buddhist altar

- Yamagata Buddhist altar

- Yame-fukushima Buddhist altar

- Nagaoka Buddhist altar

- Sanjo Buddhist altar

- Niigata-shirone Buddhist altar

- Owari Buddhist altar equipment