- Lacquerware

- Akita

Kawatsura lacquerware Kawatsura shikki

Made with Tohoku's abundant forest resources

Durable lacquerware for everyday use

Description

What is Kawatsura lacquerware ?

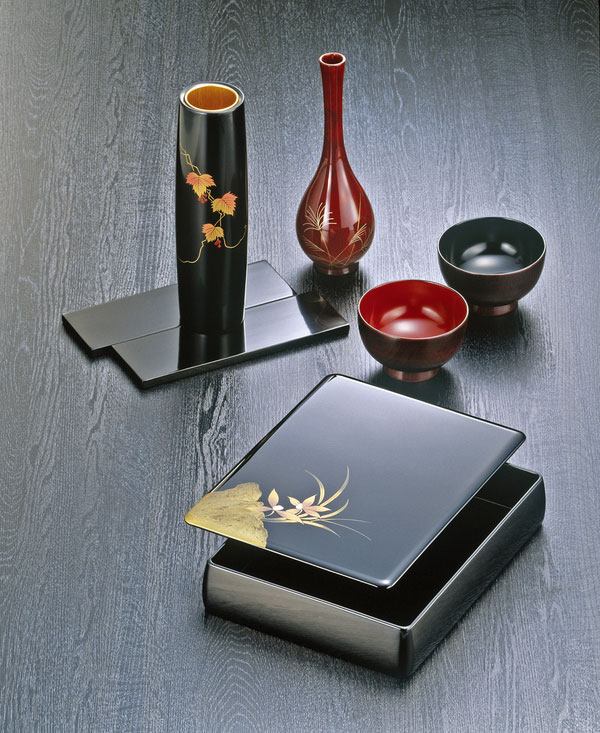

Kawatsura lacquerware (called Kawatsura shikki in Japanese) is produced in the town of Kawatsura in the southern part of Akita prefecture. Everyday use items like bowls and trays have been produced here for a long time.

Kawatsura lacquerware has excellent durability while being reasonably priced. Among the production process steps of lacquerware, undercoating is important for making the wood strong. This involves repeating processes of charcoal application, in which a mixture of persimmon juice and charcoal powder is applied. Then it is dried, polished and persimmon juice is applied before it is polished again. Finally, an undercoating of raw lacquer is applied. It is the repetition of this work that gives Kawatsura lacquerware its durability. Also, the low production cost of persimmon juice and charcoal powder means that this durable lacquerware can be sold at a moderate price. Hananuri, an advanced finishing technique that produces a smooth surface by leaving the coating applied after drying, without polishing gives an affection to the product.

Today, bowls comprise around 60% of production, but there are many items that are adapted to modern life while retaining tradition, from small items to large furniture.

History

The history of Kawatsura lacquerware begins in the Kamakura period (1185–1333). It is said to have begun when Michinori ONODERA allowed peasants to use the abundant forest resources and lacquer trees for lacquering weapons as a side business. This activity started in Kawatsura, an agricultural town, because of the difficult life and poverty from having long, harsh winters.

Around the middle of the 17th century, lacquerware production began in earnest as a local industry. At that time, there was a record of twenty six houses around the village of Kawatsura running bowl production businesses. In the second half of the Edo period (1603-1868), items for daily use such as bowls, trays, and stacked boxes came to be widely produced, under the protection of the domain, and decorations such as chinkin (gold-inlay lacquerware) and maki-e (gold/silver lacquer) started to be applied. The market even reached other countries, expanding the industry even more.

Steady growth was achieved during the postwar slump and in 1976, Kawatsura lacquerware was designated as a traditional craft. Today, products are manufactured in a wide range of fields while maintaining the same excellent techniques and traditions.

General Production Process

- 1. Wood

Wood such as beech and Japanese horse chestnut are used for round pieces like bowls. Magnolia, Japanese cedar, and cypress are used for square pieces such as stacked boxes and for round trays. Kawatsura lacquerware is produced by the abundant forest resources at the base of the Ou mountain range in Akita prefecture. The trees that provide wood are at least two hundred years old, and thorough mountain maintenance is done to prevent deforestation.

- 2. Wood collection

Wood is cut into round slices. Then, the wood is cut to an approximate size suited to its future use, while avoiding knots or damaged parts, and turned into block shapes.

- 3. Rough sawing

This step involves cutting the collected block-shaped wood into the form of the container. Wood is mounted on a lathe and the inside is cut out while the outside is roughly sawn. Afterward, it is boiled to remove tannin from the wood. This also prevents the wood from bending and provides protection from insects.

- 4. Drying

In order to further protect the wood from being warped, the articles are placed inside a room where smoke circulates for a period of one month. The wood smokes and dries so that the amount of moisture becomes around 10%.

- 5. Sawn finishing

This is the final wood base process. Dried wood is again mounted on a lathe and the surface is sawn with a hand plane to produce a smooth, beautiful finish. The base of the bowl is sawn to further complete the bowl shape.

- 6. Charcoal application

Next is the process of undercoating, which is a unique feature of Kawatsura lacquerware. A mixture of persimmon juice and charcoal powder is applied onto the piece with a straw brush. Then it dries and is polished. Finally, a coating of persimmon juice is applied before the items dries and is polished again.

- 7. Undercoating

A paintbrush produced from the tail of a horse is used to apply the raw lacquer so that it is rubbed in. By repeating the persimmon juice polishing and this undercoating step five to six times, the wood grain will be prevented from having moisture permeate, and pieces can be finished as durable lacquerware without any warping. This is the final undercoating process.

- 8. Intermediate coating, final coating, and hananuri

After undercoating, progress is gradually made from intermediate coating to final coating while adjusting the hue of the lacquer in order to reach the finishing color. The coating and polishing process is repeated six to seven times, but on each occasion it is necessary to thoroughly dry the lacquer before applying the next layer. Precise perception of subtle changes to lacquer caused by temperature or humidity is crucial.

Then a finishing technique called hananuri is done. This involves drying the item after applying lacquer, but without polishing. To prevent uneven coating, brushstrokes or dust on the items, advanced technique and careful attention is required.

Depending on the item, chinkin (gold inlay carving) or maki-e (gold or silver lacquering) is applied in order to give a more brilliant finish to the lacquerware.

Kawatsura lacquerware is completed by splitting the production process jobs among many artisans. Due to the many steps involved, it takes approximately one year to finish each item.

Where to Buy & More Information

Yuzawa Kawatsura Lacquerware Traditional Crafts Center

-

Address

-

Tel.+81-183-42-2410

-

ClosedThursdays and December 31 to January 5

-

Business Hours9am to 5pm

-

Website

See more Lacquerware

- Wajima lacquerware

- Kamakura-bori lacquerware

- Tsugaru lacquerware

- Aizu lacquerware

- Yamanaka lacquerware

- Kawatsura lacquerware

- Echizen lacquerware

- Joboji lacquerware

- Kiso lacquerware

- Hidehira lacquerware

- Kagawa lacquerware

- Ryukyu lacquerware

- Takaoka lacquerware

- Wakasa lacquerware

- Hida-shunkei lacquerware

- Ouchi lacquerware

- Kanazawa lacquerware

- Kishu lacquerware

- Kyo laquerware

- Odawara lacquerware

- Naruko lacquerware

- Niigata lacquerware

- Murakami carved lacquerware