- Lacquerware

- Kagawa

Kagawa lacquerware Kagawa shikki

Vivid color variations and impressive techniques

Original crafts inspired by South Asian traditions

Description

What is Kagawa lacquerware ?

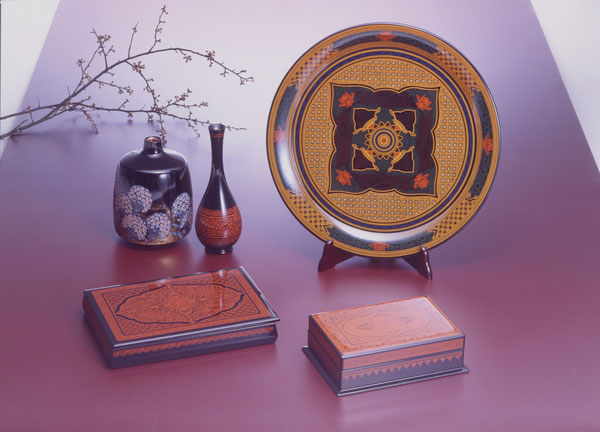

Kagawa lacquerware (called Kagawa shikki in Japanese) is produced in the area around the city of Takamatsu, Kagawa prefecture. There is a wide range of products, such as cake boxes, trays, low tables, and display cases, which are widely popular for use in daily life.

The abundant variety of product types features beautifully elegant multi-colored lacquers. This lacquerware is resistant to breakages, has a mellow feel and a beautiful glaze that stays the same over a long period of time even with use.

The representative technique of this craft was established because of master craftsman Zokoku TAMAKAJI's studies of lacquerware imported from China and Thailand in the latter part of the Edo period (1603-1868). Ancient lacquerware techniques such as kinma and zonsei have been passed down to modern times and continue to be used. The name kinma is said to derive from the actual name of a Thai plant. This process involves filling line-engraved patterns with colored lacquer, one color at a time. The work is carried out repeatedly, and the surface is flatly polished once all patterns have been filled. Zonsei is a technique that was conveyed to Japan from Southeast Asia by way of China, and this process involves applying colored lacquer to lacquer surfaces that are black, red, yellow, or other colors, to line-engrave or draw with hairlines the outlines and main parts of pictures.

History

Kagawa lacquerware was protected by the administration of the Edo period, which contributed to its steady growth in terms of quality and production volume. In 1638, Yorishige MATSUDAIRA moved to Takamatsu to be the

Another celebrated name is that of Taihei GOTO, who produced the lacquering technique known as gotonuri. Masters such as Isoi JOSHIN and Kodo OTOMARU, who are designated as holders of techniques that are Important Intangible Cultural Assets, also played great roles in the development of Kagawa lacquerware.

In 1949, Kawaga received the designation of being an important lacquerwork industrial park and the annual amount of Kagawa lacquerware production reached approximately twenty-five billion yen. More than seventy lacquer artists have been awarded prizes at exhibitions and about two thousand people work in connection with lacquerware.

Production Process

- 1. Wood coating

This production process is introduced based on zokoku lacquering, which is the leading example of Kagawa lacquerware techniques. Zokoku lacquering is a technique named after its inventor, Zokoku TAMAKAJI.

Raw lacquer is coated onto a plain wood grain of hollowed-out Japanese horse-chestnut. Any coating left on the wood base at this stage will affect the solidity of the finished product. The careful coating of all surfaces is an important step because it forms the basis of all subsequent processes. After coating with raw lacquer, the pieces are dried for a day inside a container called a muro. This is because the subsequent step can only be done once pieces have been thoroughly dried.

- 2. Wood base polishing

The wood base is polished with a lathe to make the surface smooth. This process is done meticulously to ensure that there are no rough parts or splinters on the wood base. Polishing the base improves the adhesiveness of the coating process.

A mixture of unrefined sap of lacquer trees with sawdust from Japanese zelkova trees is applied to holes made by bugs on the wood base. It is also used to coat parts of the wood base that are concave. After drying, paper is used to smooth surfaces out with paper to improve the adhesion of lacquer coating.

- 3. Layered coating

Layered coating is repeated several times using only raw lacquer with water between each coat. This step is essential in order to further strengthen the adhesion of coating. Since it takes approximately one day for lacquer to dry, five layers of coating, for example, would take at least five days to dry. It is important that the surface has properly dried before moving on to the next step.

- 4. Overcoating

Raw lacquer is used like an adhesive. Overcoating is done with Manchurian wild rice, a type of orchard grass that naturally grows on riversides in the wild next to ponds and rivers. The spores of the grass are ground into a black powder before use. In zokoku lacquering, the black powder of Manchurian wild rice is placed inside the wood base pattern to produce a black glaze. After overcoating, excess Manchurian wild rice powder is brushed off.

Lacquer is a painting material that increases water resistance, and when mixed with substances such as glue, becomes an all-purpose solvent that can be used as an adhesive. Therefore in order to produce glaze, lacquer is applied with a pad and excess lacquer is wiped off with a cloth.

- 5. Polishing

In the case of tateurushi-nuri lacquering, charcoal is used to make the surface smooth and improve the adhesion of layered lacquer. Kneaded colored lacquer is coated with shuai or light brown lacquer using a paintbrush, dried, and then a glaze is produced. Goto-nuri lacquering has distinctive speckles, and after coating on top of the intermediate coating with shuai lacquer to which red has been added, speckles are drawn using one's fingertips before the lacquer dries. The speckling technique produces different patterns depending on whether the fingers are used to strike the piece or to stroke it.

Other glazing techniques include kinma, zonsei, and choshitsu.

Facility Information

Kagawa Prefectural Shoko Shoreikan

-

Address

-

Tel.+81-87-833-7411

-

ClosedDecember 29 to January 1

-

Business Hours8:30am to 5pm

-

Website

Related Artists

- You will be redirected to the artist's page on the Gallery Japan website

Other Lacquerware

- Wajima lacquerware

- Kamakura-bori lacquerware

- Tsugaru lacquerware

- Aizu lacquerware

- Yamanaka lacquerware

- Kawatsura lacquerware

- Echizen lacquerware

- Joboji lacquerware

- Kiso lacquerware

- Hidehira lacquerware

- Kagawa lacquerware

- Ryukyu lacquerware

- Takaoka lacquerware

- Wakasa lacquerware

- Hida-shunkei lacquerware

- Ouchi lacquerware

- Kanazawa lacquerware

- Kishu lacquerware

- Kyo laquerware

- Odawara lacquerware

- Naruko lacquerware

- Niigata lacquerware

- Murakami carved lacquerware