- Dyed textiles

- Tokyo

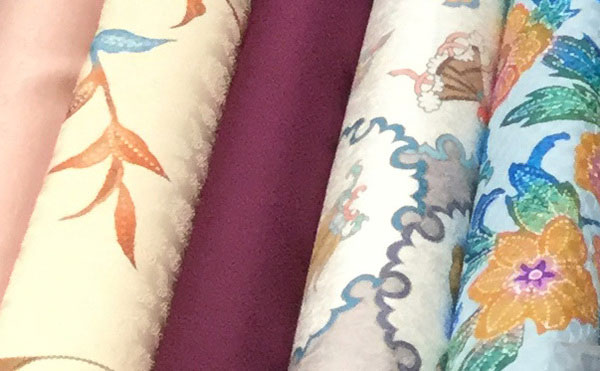

Tokyo textiles Tokyo tegaki yuzen

Elegant, beautiful handmade patterns

Depicting the culture of the Edo period

Description

What is Tokyo textiles ?

Tokyo Tegaki Yuzen are kimono textiles produced in Shinjuku Ward, Nerima Ward and Nakano Ward, Tokyo. Having been produced in the townsmen culture of Edo (current Tokyo), a refined stylishness is expressed in its soft, subdued colors. Unlike other Yuzen fabrics, Tokyo Tegaki Yuzen adopts integrated production in which the whole process is performed alone, allowing an artisan’s individuality or characteristics to be shown. The production process is almost the same as Kyo Yuzen and Kaga Yuzen, except for one point that Tokyo Tegaki Yuzen does not use patterns. As “Tegaki” means “hand painting", Tokyo Tegaki Yuzen is completely hand-painted without using patterns. Its signature designs include the Edotoki pattern, Goshodoki style pattern and Yusoku pattern. Today, Tokyo Tegaki Yuzen produce modern Tokyo style designs and colors additional to the traditional Edo style.

History

The beginning of Tokyo Tegaki Yuzen dates back to around 1800. A craftsman, Yuzensai MIYAZAKI, is said to have started Tokyo Tegaki Yuzen in the mid Edo period (1603 - 1868) when Edo (current Tokyo) became the center of politics and various people and things gathered in the city of Edo. Yuzensai Miyazaki was originally a painter of folding fans, but the patterns he painted for a kimono at the request of a kimono shop became popular, and Tokyo Tegaki Yuzen started to be made by painters and dyers who moved into Edo. As clean water is necessary to produce Tokyo Tegaki Yuzen, the craftsmen gathered around the Sumida River and other rivers. The sumptuary laws prohibiting luxury and sumptuousness are thought to have lead to the popularity of Tokyo Tegaki Yuzen, as it is said that the kimono shop, unable to sell luxurious tie-dyed kimonos and kimonos with colorful embroidery, asked Yuzensai Miyazaki for his help. The beautiful, innovative designs attracted the people and Tokyo Tegaki Yuzen have been produced up to this day.

General Production Process

- 1. Planning the design

Yuzen designs are decided considering the wearer or the purpose of wearing the kimono. Rough sketches are drawn, and sometimes the sketches are colored during this process.

- 2. Rough sketch

A rough design is sketched on white cloth using aobana-eki with a fine-point brush. Aobana-eki is a natural pigment from a plant called spiderwort that is instilled into a piece of traditional Japanese paper (washi) and then squeezed out of the piece of paper wetted with a small amount of water.

- 3. Resist dyeing paste

Paste is applied to the outline of the design drawn on the fabric for resist dyeing, so that the colors don't mix when the colors are applied. A funnel-shaped tube made with persimmon tannin-applied paper with a thin metal stick at the tip is used in this process. This process is called itomenori-oki in Japanese, as the action of applying paste looks like thin thread (ito in Japanese).

- 4. Coloring

This process is putting color dyes on the design using a special Yuzen table, where there is space in the middle of the table to place a heater. Rather than painting the colors, this process is more like putting dyes on to instill them into the fabric. The heater installed in the table is used to dry the fabric from the back during the process to prevent smearing. This coloring process is done carefully, checking the colors beforehand on a piece of the same fabric.

- 5. Masking

This is a masking process to apply paste on the color dyed places with a spatula to prevent the colors from mixing when dyeing the ground color. It is important to keep air out of the paste during this process. If there is any air in the paste, the colors may get mixed. Once the fabric is coated with the paste, it is sprinkled with bran powder to keep the paste from touching other cloth and also to keep the the paste intact during the process of dyeing the ground color.

- 6. Dyeing the ground color

This process is dyeing the ground color of the fabric. A big brush is used to avoid the fabric from drying and making color spots during the process. This process must be performed out of sunlight and reflections to dye the fabric evenly.

- 7. Steaming and washing

Steaming is carried out to fix the dyes on the cloth, and the steamed cloth is washed with water to rinse off paste, aobana-eki and excess dyes. The process of washing is called Yuzen nagashi as this was performed in the river, but today it is usually done in a water tank.

- 8. Smoothing

This process is smoothing the cloth with steam to remove wrinkles and to straighten and fix the width of the cloth. The smoothing method is either done by hand using a steamer or by machine depending on the cloth.

- 9. Finish

The finishing process involves correcting the colors with different kinds of brushes and decorating the fabric with gold leaf or gold powder or sometimes embroidery. Usually, this is the final process, but if a family crest is added, the fabric undergoes another process after this.

- 10. Painting the family crest

This process is crest drawing where the crest painter draws a family crest by hand. This is usually done on ceremonial kimonos and formal kimonos for married women. Drawing a family crest is called uwae, which had been part of dyeing, but became a specialized form in the middle or late Edo Period.

Where to Buy & More Information

Katsushika Dento Sangyokan

-

Address

-

Tel.+81-3-5671-8288

-

ClosedMondays and Tuesdays

-

Business Hours11am to 5pm

-

Website

See more Dyed textiles

- Kaga textiles

- Kyo textiles

- Tokyo fine-patterned dyeing

- Nagoya textiles

- Kyo-komon textiles

- Arimatsu tie-dyeing

- Ryukyu traditional textiles

- Tokyo textiles

- Kyo dyed textiles

- Nagoya kimono-dyeing

- Kyo kimono-dyeing

- Naniwa Honzome Hand Dyeing

- Tokyo Honzome Chusen

- Tokyo Plain Dyeing

See items made in Tokyo

- Edo kiriko cut glass

- Edo wood joinery

- Edo glass

- Murayama-oshima tsumugi silk

- Tokyo silverware

- Edo patterned paper

- Tokyo fine-patterned dyeing

- Edo bamboo fishing rods

- Tama brocade

- Hachio island silk

- Woodblock prints

- Tokyo textiles

- Edo-sekku doll

- Edo Hyogu (Art Mountings)

- Edo Oshi-e Pictures on Embossed Fabric

- Edo tortoise shell crafts

- Tokyo Honzome Chusen

- Tokyo Koto (Japanese Harp)

- Tokyo Plain Dyeing

- Tokyo Shamisen

- Tokyo antimony craft