- Dyed textiles

- Kyoto

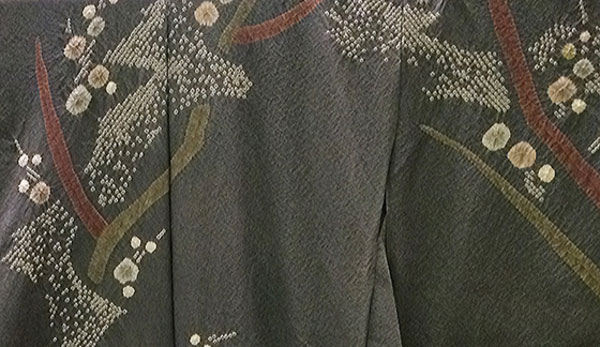

Kyo dyed textiles Kyo kanoko shibori

Time and patience make very detailed fabrics

in a rainbow of bright colors

Description

What is Kyo dyed textiles ?

Kyo Kanoko Shibori is a dyed textile produced in Kyoto Prefecture. Shibori is one of the tie-dye techniques that create patterns by tying the textile before dyeing so that the tied parts remain white. This particular Shibori resembles fawn spots and naturally enough it came to be named Kanoko Shibori. Kanoko means fawn spots in Japanese. There are more than 50 different techniques, including the two mainstream techniques hitta shibori and hitome shibori. A Shibori craftsman masters one technique and hand ties the knots one by one and dyes the textile in accordance with the method. The characteristic of Kyo Kanoko Shibori is the complicated and delicate tied knots. The distinctive three-dimensional patterns created by these minutely tied knots are unique to Kyo Kanoko Shibori. It takes a longer period of time to complete one bolt of Kyo Kanoko Shibori compared to other dyed textiles. Sometimes it takes a year and half to produce a bolt of an overall tie-dyed textile, or more than two years to produce a bolt of textile for furisode, a long-sleeved kimono. For a long time the skills of Kyo Kanoko Shibori have been passed down from generation to generation as a Japanese clothing fabric for making kimono and obi belts. Nowadays, with the craftsmen flexibly adjusting to the recent trend, the textile is found being used for modern fashion items as well as interior items.

History

Shibori dyeing is a popular tie-dye method found all over the world. It is considered to have begun in India; the technique was brought to Japan with Buddhism, and spread all over the country by the 6th and 7th century. The oldest record of Shibori dyeing is found in the Manyoshu (a collection of poems) edited in the early Heian period (794 – 1185). By the 10th century, Shibori patterns were used on court costumes. From the Muromachi period (1338 – 1573) to early Edo period (1603 – 1868), the Shibori design, Tsujigabana zome took the world by storm. Shibori techniques were refined in various parts of Japan, and Kanoko, Kanoko Shibori and Kyo Kanoko Shibori techniques were established in Kyoto. The peak of popularity was at the end of the 17th century. Shibori dye fabrics suffered a temporary setback when the sumptuary regulations were enacted and Shibori was classified as one of the luxury goods of the time, but fortunately production started again and the highly skilled techniques have continued to be handed down through the generations until today. Like other traditional crafts, the Kyo Kanoko Shibori industry is now suffering from the lack of successors. To encourage newcomers, a variety of events, workshops and exhibitions are organized to attract young people.

General Production Process

- 1. Planning the composition and design The painter draws a rough sketch based on the design that the painter and manufacturing wholesaler decided on together.

- 2. Carving the pattern The design pattern is made by cutting small circles and thin lines on the pattern paper in accordance with the design.

- 3. Printing the design The design is printed on the textile using the pattern paper and a brush. Ink that can be washed out with hot water, such as spiderwort ink is used. It is possible to recognize the exact technique being used from the cut circles and lines on the pattern paper. There is also a method where the design is painted directly on the fabric without using a pattern paper.

- 4. Tying for the shibori pattern Hikita Shibori and Kanoko Shibori are the main Kukuri (tie-dyed textile) techniques. The fabric is tightly tied by hand with silk thread to create the patterns. This tying process requires a high-level of skill and much time, and is very important as it decides the final quality of the textile.

- 5. Bleaching The spiderwort ink used to print the design is bleached; this also removes any other marks or blemishes on the fabric.

- 6. Dyeing in different colors Each color used for dyeing the fabric is dyed separately. Oke shibori and boshi shibori are methods to prevent the textile from being dyed. Oke shibori is sealing the parts to remain undyed in a wooden tub before dipping in the dye. For boshi shibori the parts to remain undyed are covered with bamboo bark or plastic held firmly in place with threads. These processes are done by special craftsmen called okeya. This is also an important process that greatly influences the final quality of the product.

- 7. Dyeing Every color requires a separate dyeing process, so the dyeing is repeated as many times as the number of colors. To dye the textile, the textile is placed directly in the dye, but the parts that require more detailed dyeing may be colored by hand using a brush.

- 8. Steam ironing to finish When the threads tied to make the shibori pattern are removed, the tied parts are white. The fabric is steamed to remove wrinkles and to even out the width.

Where to Buy & More Information

Kyoto Museum of Crafts and Design

-

Address

-

Tel.+81-75-762-2670

-

ClosedDecember 29 to January 3

-

Business Hours9am to 5pm

-

Website

See more Dyed textiles

- Kaga textiles

- Kyo textiles

- Tokyo fine-patterned dyeing

- Nagoya textiles

- Kyo-komon textiles

- Arimatsu tie-dyeing

- Ryukyu traditional textiles

- Tokyo textiles

- Kyo dyed textiles

- Nagoya kimono-dyeing

- Kyo kimono-dyeing

- Naniwa Honzome Hand Dyeing

- Tokyo Honzome Chusen

- Tokyo Plain Dyeing