- Other crafts

- Kyoto

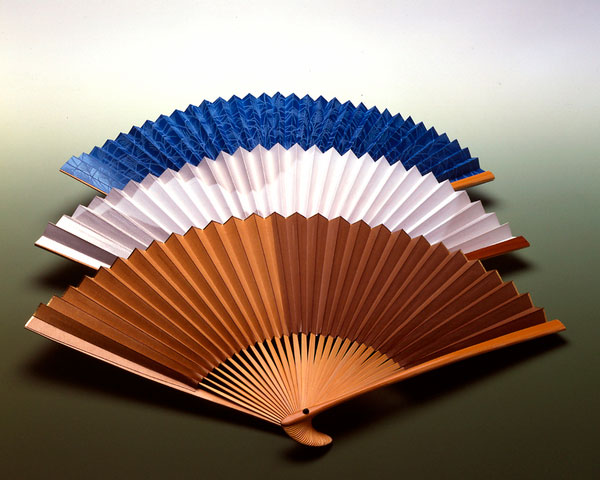

Kyo folding fans Kyo sensu

87 steps to create this masterpiece

A part of Noh theater, wedding ceremonies and outdoor events

Description

What is Kyo folding fans ?

Kyo folding fans (called Kyo sensu in Japanese with sensu meaning folding fan) are mainly produced in Kyoto. From ancient times they have been valued as high quality art works because of their beautiful designs with gold or silver leaves or gold lacquer (maki-e). Kyo folding fans are mainly made of carefully selected bamboo and paper or silk. The type of bamboo used is light and flexible which makes it ideal for the fan ribs.

Kyo folding fans are notable for their wide variety of styles that are suitable for a range of occasions whether it is a wedding ceremony or just everyday use. To name a few, there is hiogi made by stacking many thin Japanese cypress wood slats, kawahoriogi (literally a "bat's wing") made by pasting Japanese traditional paper (washi) on five to six thin ribs, maiogi used on the Noh stage (a traditional Japanese musical play), chaogi for tea ceremonies, and shukugisen for any official ceremonies or events. Kyo folding fans are categorized into two types: hariogi (pasted fan) and itaogi (plated fan) based on materials and manufacturing methods . For hariogi fans there is a kamisen (paper fan) and a kinusen (silk fan), while itaogi is made by stacking thin slats of an aromatic tree like white sandalwood.

The main common point between each of these types is that they all require a large number of artisans involved in the production of a single fan. It is said there are about 87 production processes which each require craftsmanship and time. Kyo folding fans are not only carefully handcrafted and beautiful, but they are also useful in daily life, flexible from pliable fan ribs, and ideal for gentle breezes.

History

It is thought that the first Kyo folding fans were derived from long, thin wooden tablets called mokkan dating from the early Heian period (794-1185). A folding fan discovered inside a Buddhist statue in Toji Temple, Kyoto, is considered to be Japan's oldest fan. The fan was a hiogi and inscribed with the characters "the first year of the Genkei period" or the year 877.

In the middle of the Heian period, kawahoriogi became popular as summer fans while hiogi were made for emperors and princes. During the Muromachi period (1336-1573), Japan was influenced by Chinese fans and kamisen which are made of bamboo and paper first appeared. From the Heian period, folding fans were not just to serve the useful purpose of fanning, they had also become an essential part of social etiquette and gift giving. However, it was not until the Muromachi period that production began for the fans used in Noh theater, incense art, and tea ceremonies.

Around the 13th century, the distribution of folding fans went from being domestic only to international with exports going to countries like China and India. It is said that Kyo folding fans changed the shape of Western fans by making their way to Europe via India. The reimport of fans that had been exported overseas led to kinusen type fan using silk or cotton cloth being created.

General Production Process

- 1. Cutting bamboo

In order to make the fan ribs, the bamboo is cut horizontally and the nodes (joints) are removed.

- 2. Splitting bamboo

After steaming the bamboo, it is sliced finely to the width of the fan's rib by using measurements and a small knife or mallet.

- 3. Carving the ribs

After a rough hand planing or shaping to separate the bamboo's white interior layer from the exterior bark, the exterior bark is planed thinly on both sides. Then the bamboo is left to dry for a day and night.

- 4. Drilling

After drilling a hole in the base of the ribs, they are threaded onto a bamboo or metal skewer and left to soak and soften in water for two to three days.

- 5. Shaping

Dozens of skewered ribs are laid out on a worktop and then cut and shaved to its final shape with a chisel and a uniquely-shaped knife called a wakikaki.

- 6. Air drying

In order to remove the blue color from the bamboo, the shaped ribs are left outside to air dry in the sun.

- 7. Polishing

A tool made of wild boar tusk is used for polishing.

- 8. Fitting the rivet

The ribs are riveted, trimmed and the ends are planed with a kanna or Japanese hand plane in preparation for being inserted into the fan paper. The thinned and narrowed section of the rib is known as nakabone.

- 9. Paper processing

The preparation of paper for the fan consists of a process called awase, drying, and cutting the fan shape. Awase is pasting shell paper onto both sides of the core paper. This is a difficult task that requires skillful glue application as it is important for the core paper to separate into two layers when the thinned ribs are inserted. After pasting and drying, the layered sheets are cut into the fan shape.

- 10. Foil decoration

The fan-shaped paper is sometimes decorated with gold leaf. With a bamboo spatula, gold leaf is cut on buckskin or on the ground into gold dust and then sprinkled on the paper. It could also be applied directly to the design. Both techniques add gorgeous foil decoration to Kyo folding fans. Moreover, for the plain pressing technique found only in Kyoto, extremely thin gold leaf covers the whole paper.

- 11. Painting, woodblock printing

In this stage, a picture is drawn on the paper using colors mixed with glue, and applied with a single brush or multiple brushes attached together. In addition to hand drawing, decoration is applied using techniques like kirigata surikomi or tsukihan, which are unique to Kyoto.

- 12. Folding

After a bamboo spatula is used to split the pasted core paper into two layers, then the damp paper is inserted between folding molds, and each crease is individually folded.

- 13. Opening

Using a thin bamboo tool, a space to insert each rib is created in the space of the paper that was split into two layers.

- 14. Cutting

So that it is the correct size, the excess paper at the top and bottom of the paper is removed using a large blade.

- 15. Finishing touches

This process consists in blowing up and inflating the space in the fan's paper created during the opening process in order to ease the insertion of the glue coated ribs. The larger the number of ribs, the narrower the space to insert them is, which why a high degree of craftsmanship is important for this step.

- 16. Attaching the side guards

Side guards (called oyabone) of the fan are warmed so they bend inward. This step ensures the fan closes tightly and helps produce the characteristic sharp snapping sound. Finally, glue is applied to the inner side of the side guards, and attached to both ends of the paper and left to dry.

Leading Ateliers

Hakuchikudo atelier

We have preserved the traditions of the Kyo folding fans while adding different modern touches for a new look. We created collections with different artists and other industries and all our fans are hand-made using many different materials by highly skilled artisans. Our contemporary fans can accessorize any look while bringing some folklore to your everyday life.

-

Founded1718

-

ClosedWednesdays (open every day from May to August)

-

DirectorNoriyuki YAMAOKA

-

Business Hours10am to 6pm/7pm from May to August

-

Address

-

Website

-

Tel.+81-75-221-1341

Yamani

Our folding fans are all carefully inspected one by one to make sure that we can provide our customers with the best quality.

From the design and production to shipment, our fans are created by highly skilled professionals.

-

Founded1713

-

ClosedSaturdays, Sundays, holidays, around the New Year and during Bon festival

-

DirectorKiichiro YAMANAKA

-

Business Hours9am to 5pm

-

Address

-

Website

-

Tel.+81-75-351-2622

Where to Buy & More Information

Kyoto Museum of Crafts and Design

-

Address

-

Tel.+81-75-762-2670

-

ClosedDecember 29 to January 3

-

Business Hours9am to 5pm

-

Website

See more Other crafts

- Edo kiriko cut glass

- Koshu lacquered deer leather

- Kyo folding fans

- Marugame uchiwa fans

- Boshu uchiwa fans

- Gifu lanterns

- Yamaga lanterns

- Kyo uchiwa fans

- Tendo Japanese chess pieces

- Edo glass

- Edo patterned paper

- Yame lanterns

- Owari Cloisonné

- Fukuyama Koto (Japanese Harp)

- Kyo art preservation

- Banshu fly-fishing flies

- Woodblock prints

- Koshu hand-carved seals

- Edo Hyogu (Art Mountings)

- Edo tortoise shell crafts

- Etchu Fukuoka Sedge Hats

- Gifu Japanese Umbrellas

- Nagasaki tortoise shell crafts

- Nagoya Sekku Kazari

- Sanshin

- Tokyo Koto (Japanese Harp)

- Tokyo Shamisen