- Dyed textiles

- Aichi

Arimatsu tie-dyeing Arimatsu narumi shibori

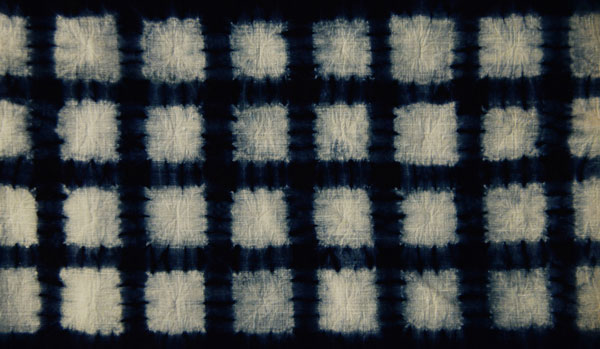

Contrast between the shades of cotton and indigo

Classic example of tie-dye renowned throughout the world

Description

What is Arimatsu tie-dyeing ?

Arimatsu Narumi Shibori is a tie-dye fabric produced in the area surrounding Nagoya, Aichi prefecture. Many of the tie-dye products in Japan are produced here. The tie-dye products are designated as a traditional national craft. Arimatsu Narumi Shibori is also referred to as Arimatsu Shibori or Narumi Shibori. This craft is known for the contrast in shading that is created when the fabric is tied and the distinctive texture of the pattern. Currently, there are more than a hundred kinds of tie dyeing methods available, including nuishibori (sewing and tying before dyeing), kumo shibori (spider- web shaped pattern), sekka shibori (flower pattern), Miura shibori (tie-dye method invented by the wife of a doctor in Oita), and kanoko shibori (dappled pattern). The 1st International Shibori Symposium was held in 1992 and since then the shibori (tie-dye) network has spread around the world. The Arimatsu area and Narumi area are now regarded as the mecca of shibori. Now these tie-dye patterns are acknowledged as "SHIBORI" all over the world.

History

Arimatsu Narumi Shibori originated in the early Edo period (1603 – 1868). Although the technique of shibori started in the Nara period (710 – 794), Arimatsu Narumi Shibori was first created when people from Bungo (currently Oita prefecture) came to help build Nagoya castle which was under construction between 1610 and 1614. After seeing the shibori kimono worn by the people from Bungo, Shokuro TAKEDA who had settled in Arimatsu, made a towel using the shibori technique with Mikawa cotton (cotton produced in Aichi Prefecture). That marked the beginning of Arimatsu Narumi Shibori.

A woman from Bungo conveyed the Bungo Shibori technique in 1655 and Arimatsu Shibori changed from then on. The technique is referred to as Miura shibori. Arimatsu had been the center of production for a long time, but the names Arimatsu Shibori and Narumi Shibori were established when travelers started buying the shibori products as souvenirs at Narumi-Juku which was one of the 53 stations of the Tokaido. As Arimatsu and Narumi were incorporated into Nagoya City, the name of the product became Arimatsu Narumi Shibori.

Production Process

- 1. Preparing the paper pattern

Once a product plan is made and the design is decided, a paper pattern is made along with the design. This is done by cutting out the pattern using a small sharp knife and hollow punch.

- 2. Printing the design

The design is printed on the fabric before the tying process. First, the fabric is starched and steamed to smooth the creases so that printing the design on the fabric becomes easier. Next, the pattern and the fabric are layered and the printer (surishi in Japanese) prints the design on the fabric. For this printing, ink extracted from Asiatic dayflower called aobanaeki, or its substitute is used. When the tying process is completed, the printed design is washed away using cold or hot water.

- 3. Tying

Shibori craftsmen tie the fabric with cotton or silk threads based on the design. A hundred or more techniques have been invented for this process, and there are specialized craftsmen for each technique. Skills and techniques have advanced over the years, and different tools are used for each technique. Typical tools used are stands for tying fabric such as theukodai or karasuguchidai, kanokodai and makiagedai. The tying process takes much time, so it used to be a side business for farmers in the surrounding area. However, recently there are many cases where this process is done overseas to reduce the labor cost.

- 4. Dyeing

A specialized craftsman called someya dyes the fabric. The tied places are not dyed so the design is made based on this feature. Generally, the soak and dye method is used for shibori, although sometimes a special method is used. The fabric is bleached to remove stains from the printing and tying processes before dyeing, and it is then dyed while being tied in various places. When more than one color is used, the fabric has to be processed to prevent it from being dyed in the wrong color. There are a number of different dyeing methods that vary according to the kind of tying and dye used, but to dye a bolt of fabric, the dyeing and resist dyeing is repeated more than twenty times. Dyes and additives appropriate for the fabric are used, and the type of dye and method of dyeing are changed depending on the usage and amount of the dye.

- 5. Removing threads

When the fabric is thoroughly dried after dyeing, the threads that were used for tying the fabric are removed. As shibori prevents the fabric from being dyed by tying, the fabric is tied especially firmly in certain places. It requires great attention to remove the firmly tied threads so that the fabric does not become damaged. The methods for removing threads also vary depending on the type of shibori, but there are roughly four methods. Removing the threads requires detailed work and it sometimes takes 3-4 days to remove threads from a bolt of fabric. As the fabric shrinks after removing the threads, it is steamed to smooth the creases and regulate the texture. Additional processing is done if necessary, and finally, it is made into a roll, or it is basted so that the design becomes visible (ebashiage), and is finished as a product.

Facility Information

Tie-Dyeing Museum

-

Address

-

Tel.+81-52-621-0111

-

ClosedAround the New Year

-

Business Hours9:30am to 5pm

-

Website

Other Dyed textiles

- Kaga textiles

- Kyo textiles

- Tokyo fine-patterned dyeing

- Nagoya textiles

- Kyo-komon textiles

- Arimatsu tie-dyeing

- Ryukyu traditional textiles

- Tokyo textiles

- Kyo dyed textiles

- Nagoya kimono-dyeing

- Kyo kimono-dyeing

- Naniwa Honzome Hand Dyeing

- Tokyo Honzome Chusen

- Tokyo Plain Dyeing

Other Crafts Made in Aichi

- Tokoname ware

- Akazu ware

- Toyohashi brushes

- Nagoya textiles

- Nagoya Buddhist altar

- Owari Cloisonné

- Arimatsu tie-dyeing

- Mikawa Buddhist altar

- Seto-sometsuke ware

- Nagoya kimono-dyeing

- Nagoya traditional paulownia chest

- Okazaki stonemasonry

- Nagoya Sekku Kazari

- Owari Buddhist altar equipment

- Sanshu Onigawara Crafts