- Other crafts

- Aichi

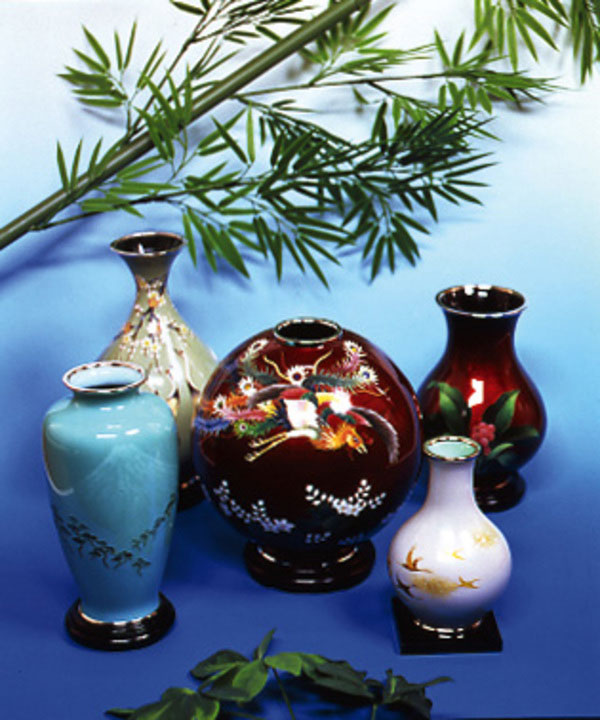

Owari Cloisonné Owari shippo

Shining examples of the finest craftsmanship

Jewels of Japan: elegance and splendor

Description

What is Owari Cloisonné ?

Owari Cloisonné (called Owari Shippo in Japanese) is a type of enamelware, produced in Ama and Nagoya, Aichi prefecture, that is decorated with vibrant colorful designs often depicting natural scenery or the beauty of nature. The name shippo refers to the seven jewels of Buddhism, as cloisonné was so beautiful it was as if they were actually inlaid with the precious stones mentioned in the Buddhist scriptures. This craft is known for having brightly colored enamel on a metal base like copper or silver and is produced with a variety of techniques. For modern cloisonné, the basic technique is yusen-shippo (wired cloisonné) which involves affixing metal wires along design lines drawn on a metal base. Enamel is applied within the wires, and the piece is fired and polished. For musen-shippo (wireless cloisonné), either the metal wires are removed before firing or no wires are used at all, which allows subtle gradation of color rather than clearly delineated borders like wired cloisonné. In moriage-shippo (raised cloisonné), sections of the enamel surface are raised above the level of the metal wires and fired to give a relief effect. Cloisonné can have a sparkling glasslike effect like the delicate shotai-shippo (plique-à-jour), which is made by fixing silver wires on a copper base, applying and firing translucent enamel, polishing, and removing the base by acid corrosion. There are many more techniques which are used in different combinations to make new techniques. The unique sparkle and colors of the cloisonné glass is fascinating.

History

Cloisonné, which started in Ancient Egypt, was introduced to Japan via Europe and China. The oldest cloisonné ware that has been found in Japan to date, was excavated from an ancient burial mound dating from around the 7th century and had been used as fittings for castles and temples. Between the years 1830-1844, cloisonné plates were imported from the Netherlands. Tsunekichi KAJI, a feudal retainer of the Owari domain (now western Aichi prefecture), studied the plates to identify and modify the manufacturing process. His technique took root in local villages as an industry undertaken by the second and third sons of farming families. The cloisonné manufacturing process rapidly spread, and the craft produced in the Owari region came to be known as Owari Shippo. As the names of individual craftsmen in Owari were not recorded or inscribed on their pieces, cloisonné production became a village artisan industry, rather than artwork by individuals. Even so, standards were so high that in 1867, Owari Cloisonné became known worldwide when it won an award at the Universal Exposition held in Paris. As a luxury item, Owari Cloisonné was greatly affected by wartime and the fall of the economy. During World War II, production was ordered to stop due to the enactment of Limitation Rules on Manufacturing and Selling of Luxury Items. However, when Shinji YOSHINO assumed the post of governor in 1943, he reinstated Owari Cloisonné as a local industry.

General Production Process

- 1. Making the base

Since each stage of Owari Cloisonné production requires highly-specialized techniques, each phase of the process is allocated to expert artisans. The first process is making the base. The copperplate, which is mainly used for the base of Owari Cloisonné, is shaped by hand by beating with a metal or wooden hammer, or by machine using an iron rod and lathe, or a press machine.

- 2. Drawing the design

There are two ways of drawing the design. Either the design is drawn directly onto the plain metal surface of the base with sumi ink, or a white enamel coating is applied first before the design is drawn. A newly-developed cutting print technique which uses a carved plastic mold is often used now, and has improved recent production efficiency.

- 3. Affixing the wires

A glue made of the dried ground roots of urn orchid is used to affix silver wires along the lines of the design.

- 4. Applying enamel

Enamel is applied between the silver wires on the metal base. Owari Cloisonné, known for its colorful designs, uses dozens of enamels made from materials like silica stone, lead oxide, or saltpeter with the addition of a small quantity of cobalt, manganese, copper, silver, or other metals to add color. To create distinctive colors, some workshops have their own secret recipes, giving artisans the opportunity to demonstrate their skill and individuality. Even with modern technology, attaching wire and applying enamel is difficult by machine, so skilled artisans with many years of experience do these tasks by hand.

- 5. Firing

After the colored enamel is applied, the piece is fired for about ten to fifteen minutes in an electric furnace at temperatures of about 700 to 800℃ (about 1292 to 1472℉). A charcoal furnace was used in the old days. Firing melts the powdered enamel, which then creates a difference between the depth of the enamel and the height of the metal wire. To raise the enamel to the height of the wire, several applications of enamel and repeated firings are needed. The temperature and firing time varies depending on the design and types of enamel used.

- 6. Polishing

After the final firing, the wire and enamel surface will still be uneven and polishing and smoothing using water and a whetstone is required. Wood charcoal or tin oxide is used for further polishing to attain a high gloss. By polishing, the wires will appear, making the outline of the design visible. In recent years, industrial diamonds are sometimes used for polishing.

- 7. Fitting ornamental rims

The upper and lower edges are not processed in the polishing stage, leaving the copper base exposed. Silver or silver-plated rims are attached. For example, for a flower vase, rings will be fitted to the rim and the bottom.

Where to Buy & More Information

Shippo Art Village

-

Address

-

Tel.+81-52-441-7588

-

Business Hours9am to 5pm

-

Access10, Tooshima, Shippo-cho, Ama-shi tsubo 119-2

-

Website

See more Other crafts

- Edo kiriko cut glass

- Koshu lacquered deer leather

- Kyo folding fans

- Marugame uchiwa fans

- Boshu uchiwa fans

- Gifu lanterns

- Yamaga lanterns

- Kyo uchiwa fans

- Tendo Japanese chess pieces

- Edo glass

- Edo patterned paper

- Yame lanterns

- Owari Cloisonné

- Fukuyama Koto (Japanese Harp)

- Kyo art preservation

- Banshu fly-fishing flies

- Woodblock prints

- Koshu hand-carved seals

- Edo Hyogu (Art Mountings)

- Edo tortoise shell crafts

- Etchu Fukuoka Sedge Hats

- Gifu Japanese Umbrellas

- Nagasaki tortoise shell crafts

- Nagoya Sekku Kazari

- Sanshin

- Tokyo Koto (Japanese Harp)

- Tokyo Shamisen

See items made in Aichi

- Tokoname ware

- Akazu ware

- Toyohashi brushes

- Nagoya textiles

- Nagoya Buddhist altar

- Owari Cloisonné

- Arimatsu tie-dyeing

- Mikawa Buddhist altar

- Seto-sometsuke ware

- Nagoya kimono-dyeing

- Nagoya traditional paulownia chest

- Okazaki stonemasonry

- Nagoya Sekku Kazari

- Owari Buddhist altar equipment

- Sanshu Onigawara Crafts