Photo:Okayama Prefecture Tourism League

Photo:Okayama Prefecture Tourism League

- Wood, bamboo crafts

- Okayama

Katsuyama bamboo crafts Katsuyama take zaiku

Crafts that grow more beautiful and age gracefully

Using them draws out the natural charm of bamboo

Description

What is Katsuyama bamboo crafts ?

Katsuyama Take Zaiku are bamboo baskets produced in Maniwa City, Okayama Prefecture. Bamboo ware products are made in many areas across Japan from a variety of bamboos such as thick stemmed bamboo and black bamboo. However, Japanese timber bamboo growing around Maniwa City is used for Katsuyama Take Zaiku. Originally, the main products were sieve baskets called souke in Japanese, used in daily life and farm work. Four types of baskets are known as typical Katsuyama Take Zaiku: ouzouke for storing grain, mizouke for carrying vegetables and other crops, komeage-zouke for draining washed rice, and meshi-zouke to hang rice under the eaves to prevent them from rotting. Today, bread baskets, hand baskets, and flower vases are also produced. Katsuyama Take Zaiku are distinguished by their durability and ease of use and they are particularly known for using minimally processed green bamboos. The bamboo crafts made of Japanese timber bamboo in other regions are made of bamboo heated over a fire or boiled, but Katsuyama Take Zaiku use completely untreated green bamboo; this production method has been traditionally passed down for many generations. These simple and solidly-made bamboo baskets make the best use of the natural beauty of green bamboo, and with the passage of time, the color changes to a cognac amber.

History

It is thought that the production techniques of Katsuyama Take Zaiku were established around 1860. However, as the baskets in those days were used in daily life, only a few examples exist today. For this reason, it is difficult to specify the year of origin, but in old documents of the Yamatani family considered to be written around 1860, and in an application for a sake brewery license in 1877, harisouki bamboo baskets and kamesofuke used to store or carry grain are mentioned. This would indicate that by at least the end of the Edo period, Katsuyama Take Zaiku were widely available and distributed. Moreover, it is known in those days, some households invited bamboo basket craftsmen to stay for several days to make baskets for a whole year, which tells us that bamboo ware were essential for people’s daily life and farm work. The crafts were sold in the Chugoku region by peddlers, and because of their high practicality, they were much appreciated as daily living necessities, and over the years they spread throughout the country. In 1979, Katsuyama Take Zaiku was designated as a national traditional craft.

General Production Process

- 1. Cutting and washing As Japanese timber bamboo used for Katsuyama Take Zaiku is minimally processed, the selection of bamboo is very important. After approximately one year of growth, the thickness and height of a bamboo does not change, but with age the color and hardness changes. Bamboo aged three to five years is the best for bamboo ware. In November and December, which is the best time to cut high quality bamboo with little insect damage, enough bamboo for a year is cut with a bamboo cutting saw. The bamboo is cleaned with a scrubbing brush to remove dirt before splitting.

- 2. Splitting the bamboo Bamboo is split in accordance with the product dimensions; this is the most difficult task, and it is said that it takes 2 to 3 years to master these skills. Firstly, bamboos cut 1 to 5 meters long are split in half lengthwise using a special hatchet. The bamboo is further split with a sharper hatchet into stakes, and the fine higo strips often measuring just several millimeters wide that will be woven around the stakes. It is important to use a very sharp hatchet as it will affect the luster of the finished product. The stakes are used for the frame and rims, and the thickness of the higo is changed depending on the purpose of use.

- 3. Weaving The basic weaving method of Katsuyama Take Zaiku is gozame-ami (mat plaiting). The higo strips made from the green outer layer and those made from the white inner layer are alternately woven to create simple but tasteful designs. In the weaving process, firstly, a frame is created based on the traditional dimensions using the stakes. The higo strips are then woven through the stakes. Beautiful patterns are created by the artisan’s skillful handwork. When the weaving is completed, the vine of a locally grown Chinese moonseed is used to bind the rim of the basket. Only products bound with moonseed vine are designated as national traditional crafts, while those products finished with wire or the like are classified as ordinary crafts.

- 4. Completion Katsuyama Take Zaiku are completely hand-made, and it is quite common for one artisan to carry out most of the production process.

Where to Buy & More Information

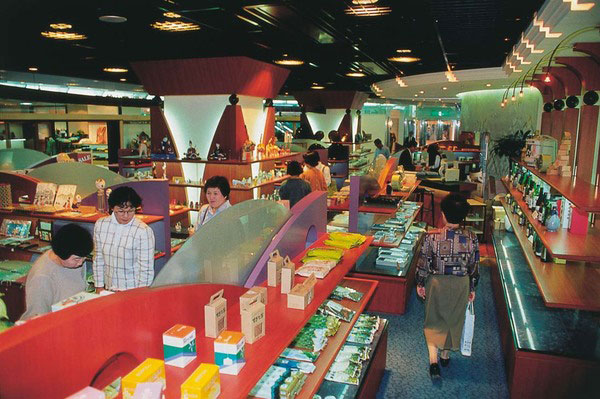

Okayama Kanko Bussan Center

-

Address

-

Tel.+81-86-234-2270

-

ClosedTuesdays

-

Business Hours10am to 7pm

-

Website

See more Wood, bamboo crafts

- Hakone wood mosaic

- Iwayado traditional chest

- Kaba cherrybark woodcrafts

- Odate bentwood

- Inami wood carvings

- Matsumoto furniture

- Beppu bamboo crafts

- Edo wood joinery

- Ichii woodcarvings

- Suruga bamboo crafts

- Edo bamboo fishing rods

- Kishu bamboo fishing rods

- Kamo traditional chest

- Kyo wood joinery

- Miyakonojo archery bows

- Osaka carved wooden panel

- Miyajima woodwork

- Nibutani carved wooden tray

- Okuaizu Basketry

- Echizen traditional chest

- Kasukabe traditional paulownia chest

- Katsuyama bamboo crafts

- Osaka karaki wood joinery

- Takayama tea whisks

- Toyooka wicker crafts

- Akita cedar tubs and barrels

- Nagiso woodturning

- Kishu traditional chest

- Nagoya traditional paulownia chest

- Osaka bamboo screens

- Osaka-senshu traditional paulownia chest

- Sendai traditional chest