Photo:Niigata Prefecture

Photo:Niigata Prefecture

- Wood, bamboo crafts

- Niigata

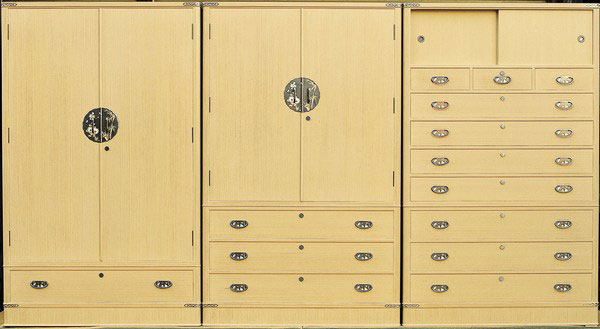

Kamo traditional chest Kamo kiri tansu

Beautiful polished wood

Paulownia's gentle texture

Description

What is Kamo traditional chest ?

Kamo Kiri Tansu are chests of drawers made of paulownia wood that are produced in and around the city of Kamo, Niigata prefecture. Today, a majority of all paulownia chests made in Japan are produced in Kamo. This craft can keep clothes safe from insects and humidity, and is fire and water resistant, all largely due to the paulownia wood. Paulownia wood is so light, flexible, and airtight that it is ideal for making high quality chests. In fact, there is an old story that, when a paulownia chest that had been washed away in a flood was dried and opened, the clothes inside were still clean despite the mud and dirty water on the outside. In addition, the wood does not catch fire easily, even if the surface is burned and carbonized, as it has a low heat transfer rate. This craft is ideal for storing clothes in the humid climate of Japan as the natural chemicals of tannin, paulonin, and sesamin prevents damage from bacteria and insects, and the chest is resistant to humidity. In addition to being highly practical, Kamo paulownia chests have a warmth and elegance that has attracted people for a long time. Their lovely white wood bark and delicate wood grain have a dignified presence, and have been produced by highly skilled artisans up to this day.

History

During the Tenmei era (1781-1789) in the Edo period, a wood joinery craftsman named Kouemon MARUYA made a chest using cedar wood, which is said to be the origin of Kamo Kiri Tansu. On the back of the earliest known paulownia chest, the words, "Purchased in 1814”, are written. Around the year 1820, paulownia boxes and chests were said to have been shipped by boat towards Niigata and other parts of the Tohoku region using the Kamo and Shinano rivers. By the beginning of the Meiji period (1868-1912), Kamo Kiri Tansu were being shipped to Hokkaido throughout the Tohoku area, and Kamo further developed as the production area of paulownia chests. A document compiled in 1877, the Kamo Choshi Shiryo (Kamo’s local history documents), records that the number of chests of drawers being produced was 400, and the number of large oblong chests for clothing being produced was 200. A type of finishing varnish called yashatoso, which is an important part of manufacturing current paulownia chests, was developed at the beginning of the Showa period (1912-1926). Today, Kamo paulownia chests are shipped nationwide.

General Production Process

- 1. Lumber production

As there are many sawmills lumbering raw wood in Kamo, unlike other production centers, every process from logging to completion of the product is done within Kamo. Felled trees are dried for three years. This requires a lot of land and labor. The timber is periodically turned and placed out in the sun, wind and rain to remove astringency, avoid discoloration, and prevent warping.

- 2. Cutting to size

Experienced artisans classify the wooden boards to the appropriate parts of the chest and assemble them. As only a third of the paulownia wood is good quality wood, artisans need years of experience to select the good quality wood and use it effectively. The wood is cut into boards, with thought given to the wood grain and overall quality of the wood, and is then assembled while heavily focusing on the appearance of the wood grains.

- 3. Assembly

Artisans cut dovetail tenons to strengthen the joints and make the body of the chest robust by using wood pegs instead of nails.

- 4. Processing of drawers and doors

The drawers and doors are made bigger than the outer frames, and then they are planed little by little to size so that there is no space between the frame and drawers.

- 5. Coating

After adjusting the wooden parts, artisans scrape off the softer wood and leave the firmer wood. Since paulownia wood is soft and vulnerable, this process increases durability and makes the wood grain stand out. Then the chest is painted with several coats of a mixture of polishing powder and Japanese green alder extract. After drying, wax is applied on the chest along the wood grain evenly.

- 6. Attaching metal fittings

To finish the chest, artisans carefully attach the metal fittings including pulls, hinges, and locks.

See more Wood, bamboo crafts

- Hakone wood mosaic

- Iwayado traditional chest

- Kaba cherrybark woodcrafts

- Odate bentwood

- Inami wood carvings

- Matsumoto furniture

- Beppu bamboo crafts

- Edo wood joinery

- Ichii woodcarvings

- Suruga bamboo crafts

- Edo bamboo fishing rods

- Kishu bamboo fishing rods

- Kamo traditional chest

- Kyo wood joinery

- Miyakonojo archery bows

- Osaka carved wooden panel

- Miyajima woodwork

- Nibutani carved wooden tray

- Okuaizu Basketry

- Echizen traditional chest

- Kasukabe traditional paulownia chest

- Katsuyama bamboo crafts

- Osaka karaki wood joinery

- Takayama tea whisks

- Toyooka wicker crafts

- Akita cedar tubs and barrels

- Nagiso woodturning

- Kishu traditional chest

- Nagoya traditional paulownia chest

- Osaka bamboo screens

- Osaka-senshu traditional paulownia chest

- Sendai traditional chest

See items made in Niigata

- Ojiya chijimi textiles

- Shiozawa tsumugi silk

- Hon-shiozawa silk

- Ojiya tsumugi silk

- Niigata lacquerware

- Kamo traditional chest

- Murakami carved lacquerware

- Tsubame-tsuiki copperware

- Echigo-sanjo cutlery

- Tokamachi traditional resist-dyed textiles

- Nagaoka Buddhist altar

- Tokamachi akashi chijimi textiles

- Echigo-yoita cutlery

- Sanjo Buddhist altar

- Niigata-shirone Buddhist altar