Photo:Miyagi Prefecture Tourism Division

Photo:Miyagi Prefecture Tourism Division

- Wood, bamboo crafts

- Miyagi

Sendai traditional chest Sendai tansu

Superb lacquered furniture with a deep wood grain

Magnificent dragon, lion, and peon decorations

Description

What is Sendai traditional chest ?

Sendai tansu is a type of chest of drawers made in the city of Sendai, Miyagi prefecture. Usually they are made of Japanese chestnut, cedar, and zelkova wood, and renowned for their highly ornamented iron fittings and three different types of beautiful Japanese lacquer coating. The making of Sendai tansu involves three different craft techniques: carpentry with no nails or screws; lacquerwork to bring out the beauty of the wood grain; and the metal chasing of the intricate designs. To complete a single chest of drawers, an average of 100 to 200 metal fittings are made in a variety of shapes with pictorial designs and motifs, such as dragons, lions, or peonies, which are traditional bringers of good luck and fortune.

History

Sendai tansu are commonly thought to originate from the time when Masamune DATE, a daimyo in the Sengoku period (1467-1568), ordered the building of Aoba Castle, and the tansu was one of the items the master carpenter made.

At the end of the Edo period (1603-1868), samurai in the Sendai domain produced Sendai tansu to supplement their income and to store their weaponry, haori (half-coat), kamishimo (ceremonial dress), and valuable documents. Therefore, the common size of the early Sendai tansu was about 120 cm wide and 90 cm high, the perfect size for storing military equipment. From the end of the Meiji period (1868-1912) through to the middle of the Taisho period (1912-1926), other articles of furniture came to be made and overall production increased, in part due to exports first to Germany and then to other European countries. The elaborate style of furniture was much appreciated both in Japan and abroad. With the coming of World War II, production was stopped, but in the post-war period craftsmen resumed production and the traditional skills are still used today.

Production Process

Photo:Miyagi Prefecture Tourism Division

Photo:Miyagi Prefecture Tourism Division

- 1. Preparing the wood

Trees are cut into logs, which are left to season for three to four years.

- 2. Cutting thick planks

The logs are cut roughly and turned into planks about 12 centimeters thick (4.7 inches) and naturally dried for some fifteen years in a well-ventilated storage place.

- 3. Cutting thin plants

After being naturally dried, the planks are cut into thinner planks of about 24 milimeters (0.9 inches) and dried indoors for a further ten or so years.

- 4. Cutting to size

The planks are measured and cut according to the size of the future chest. Zelkova wood with its beautiful grain is used for the exterior surface, cedar wood for the main body, and the interior parts are made of cedar and paulownia wood.

- 5. Processing

Particularly beautifully grained wood is cut into thinner sheets of veneer, which is backed with paulownia wood; this is to ensure the chest will adapt to a modern air-conditioned environment with no shrinkage or warping.

- 6. Assembly

The surface of the wood components are roughly planed, the joints are cut, and the chest is assembled. The drawers made of paulownia and cedar wood are planed in this step to ensure a smooth fit.

- 7. Lacquer coating

Raw natural lacquer is collected and prepared according to purpose. There are several different lacquer types: akaro, kuroro, shuai, and kuronuritate.

The raw lacquer is collected from fifteen to twenty year old lacquer trees and dried in the sun. About 95% of the water content evaporates to make akaro lacquer.

Kuroro lacquer is made by adding about 3 to 5% iron powder to the akaro lacquer. Shuai lacquer is made by adding about 30% of canola oil, pine resin, thick malt syrup, and other ingredients to the akaro lacquer. Kuronuritate lacquer is made by adding more iron powder to the shuai lacquer.

The chest is smoothed, polished, and receives its first coat of lacquer. There are three types of lacquering techniques: repeated lacquering and polishing, clear lacquering, and vermilion lacquering.

- 8. Drying

After lacquering, the chest is placed in a high-humidity room to dry. This lacquering and drying process is repeated about ten times.

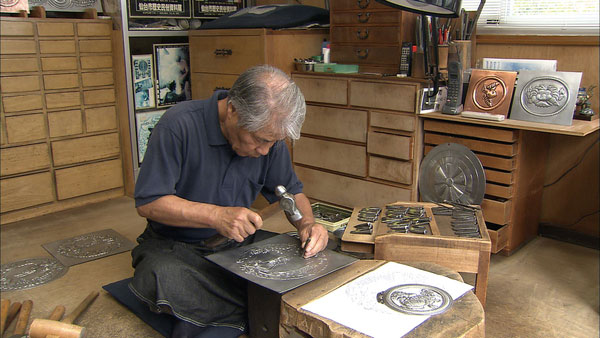

- 9. Making metal fittings

Designs are drawn on washi (Japanese traditional paper) and embossed using chisels. Depending on the design, multiple chisels may be used.

Patterns with complicated lines are done line by line, and embossed sections are hammered and raised from the reverse side.

- 10. Coating metal fittings

Each embossed fitting receives an individual and carefully applied coat of anti-rust, followed by a color coating.

The metal fittings may receive an oxidized finish or be copper- or silver-plated to give them a nice patina.

- 11. Finishing

In this last step, rust-resistant brass nails are used to affix the metal ornaments and fittings to the lacquered chest and after a final and careful inspection, the chest is completed.

Other Wood, bamboo crafts

- Hakone wood mosaic

- Iwayado traditional chest

- Kaba cherrybark woodcrafts

- Odate bentwood

- Inami wood carvings

- Matsumoto furniture

- Beppu bamboo crafts

- Edo wood joinery

- Ichii woodcarvings

- Suruga bamboo crafts

- Edo bamboo fishing rods

- Kishu bamboo fishing rods

- Kamo traditional chest

- Kyo wood joinery

- Miyakonojo archery bows

- Osaka carved wooden panel

- Miyajima woodwork

- Nibutani carved wooden tray

- Okuaizu Basketry

- Echizen traditional chest

- Kasukabe traditional paulownia chest

- Katsuyama bamboo crafts

- Osaka karaki wood joinery

- Takayama tea whisks

- Toyooka wicker crafts

- Akita cedar tubs and barrels

- Nagiso woodturning

- Kishu traditional chest

- Nagoya traditional paulownia chest

- Osaka bamboo screens

- Osaka-senshu traditional paulownia chest

- Sendai traditional chest