Photo:Hiroshima Prefecture

Photo:Hiroshima Prefecture

- Wood, bamboo crafts

- Hiroshima

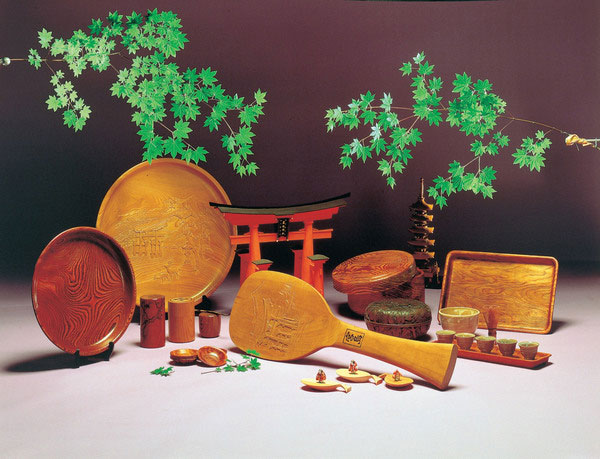

Miyajima woodwork Miyajima zaiku

Elegant woodwork souvenirs for pilgrims to the Itsukushima shrine

Warm, homely, natural wood with beautiful grain and carvings

Description

What is Miyajima woodwork ?

Miyajima Woodwork (called Miyajima zaiku in Japanese) are woodwork products made in Miyajima, Hatsukaichi, Hiroshima prefecture. Miyajima Island, one of the Three Views of Japan*, has long been nicknamed the "Island of Gods", while Hatsukaichi is a collection and distribution center of timber which makes procuring quality materials for a local woodworking industry easy. This craft has a careful finishing process in which pieces are dampened with water to purposely make the wood grain stand out before they are polished. Their rice paddles are notable for the scent of wood not transferring to the rice, with minimal rice sticking to the wood, and the region boasts the highest production output of rice paddles in Japan. Other crafts made by wood turning include round trays and tea cup saucers. There are also wood hollowed square trays. Ornamental designs of landscapes or flowers on trays, screens, and pillars are carved on the surface of trays, screens and pillars. These carvings are called Miyajima bori. Lacquering is kept to a minimum to bring out the warmth and emphasize the beauty of the wood grain.

*The Three Views of Japan or Nihon sankei are the three most celebrated scenic sights in Japan.

History

Miyajima Woodwork was first made by a Buddhist priest named Seishin around the year 1800, when he was inspired to design a rice paddle from the shape of a Japanese lute held by Benzaiten, a beloved local goddess of eloquence, music, and art. Seishin then taught the Miyajima residents the techniques of rice paddle production, which were then sold as souvenirs. Due to their high quality, the wood paddles sold well and became popular, which revived the local economy and aided the impoverished islanders. Around 1850, the technique of wood turning was brought to Miyajima and expanded the woodworking industry with the production of round trays and cup saucers. Also, a wood carver from the Koshu region (Yamanashi prefecture) named Shoshai HAKI introduced carving techniques. This increased the ornamentation on the wood pieces, attracted considerable attention, and became known as Miyajima bori (carving). By 1910, the woodwork techniques developed in Miyajima were respected so much that nearly three hundred lathe turners from all over the country gathered in Miyajima to refine their skills and learn the advanced wood turning techniques.

Production Process

- Carving rice paddles

- 1. Preparing the timber

The timber is sawn to size. A phrase often said at this step is, “make the most of the material.” This means that craftsmen should cut out the timber by carefully considering the capability and quality of the wood to minimize waste. Normally, mulberry, cypress, Japanese maple, or Japanese cherry birch is used to make rice paddles. The timber is carefully marked with a hand saw to ensure the best quality of wood, and is then sawn. The timber is roughly shaped with an adze.

- 2. Drying

The paddle is left to dry for a year or two before final shaping. Thorough drying prevents deformation and shrinkage of the wood and produces a high quality product.

- 3. Planing the face

First, a palm-sized plane which is shaped to carve round curves is used to carve the face of the paddle in the vertical direction of the wood grain. This carving is called yoko kezuri. Then, using a different plane that is capable of carving complicated curved surfaces, the face of the paddle is further carved to make the concave surface of the paddle. With a purposely blunted knife edge, the entire face is shaved and then smoothed with sandpaper. The back of the paddle is planed with the palm-sized plane along the wood grain to thin the tip of the paddle. This step determines the thickness of the paddle and is the hardest part that relies on the craftsman’s skill. Next, a small plane is used to shave any roughness before carefully smoothing and polishing with sandpaper.

- 4. Shaping the handle

The back of the handle is shaved using a curved bottom plane to give an easy-to-hold shape. The surface of the handle end is shaved with an adze, and chamfered with a small plane to give curved lines and to adjust the shape.

- 5. Polishing

The entire paddle is polished with sandpaper, and unplaned parts are shaved and smoothened. This polishing process is meticulously done multiple times.

- 6. Rubbing

Vegetable oil is applied to the rice paddle and is left for a day before being rubbed in and polished with a dry cloth. Sometimes nothing is applied in order to improve the absorbency of the wood.

- Lathe turning

- 1. Preparing the timber

Timber is carefully inspected to select the most appropriate material for the items. Usually, zelkova, mulberry, wild cherry trees, or heavily resined trunk pine is used.The timber is sawn to size and left to dry for two to three months.

- 2. Shaping

A sketch of the product is drawn on the timber, to make the most of attractive features in the grain, and sawn. Since this craft s characterized by the use of natural wood grain and minimal lacquer application, the positioning and shaping of an item is important for drawing out the best elements of the wood.

- 3. Rough turning

The sawn wood is attached to a lathe for turning. Using ten different types of circular planes, the piece is shaped roughly and excess wood is cut away with a single-edged blade. Then, a flat blade plane is used to adjust, followed by sandpaper to give a good polish. Small adjustments such as the lathe rotation speed are made by the craftsman as a result of years of experience.

- 4. Preventing cracks

After shaving roughly, the wood will develop cracks if allowed to dry right after. Therefore, an anti cracking agent or melted wax is applied on the surface before drying to prevent cracks.

- 5. Drying

The piece is left to dry thoroughly for one to three years.

- 6. Semi-finish turning

The dried piece is attached to a lathe and roughly shaved. An anti-cracking agent is applied again and the piece is left to dry. This craft is notable for taking many years between each stage as the processes are slowly completed.

- 7. Final turning

More than ten types of wood planes are used to shave the pieces to its final shape.

- 8. Final polishing

The work is carefully polished with sandpaper many times to give a good shape and finish.

Facility Information

Miyajima Dento Sangyo Kaikan

-

Address

-

Tel.+81-829-44-1758

-

ClosedMondays (open if Monday is holiday and closed the next day), December 29 to January 3

-

Website

Other Wood, bamboo crafts

- Hakone wood mosaic

- Iwayado traditional chest

- Kaba cherrybark woodcrafts

- Odate bentwood

- Inami wood carvings

- Matsumoto furniture

- Beppu bamboo crafts

- Edo wood joinery

- Ichii woodcarvings

- Suruga bamboo crafts

- Edo bamboo fishing rods

- Kishu bamboo fishing rods

- Kamo traditional chest

- Kyo wood joinery

- Miyakonojo archery bows

- Osaka carved wooden panel

- Miyajima woodwork

- Nibutani carved wooden tray

- Okuaizu Basketry

- Echizen traditional chest

- Kasukabe traditional paulownia chest

- Katsuyama bamboo crafts

- Osaka karaki wood joinery

- Takayama tea whisks

- Toyooka wicker crafts

- Akita cedar tubs and barrels

- Nagiso woodturning

- Kishu traditional chest

- Nagoya traditional paulownia chest

- Osaka bamboo screens

- Osaka-senshu traditional paulownia chest

- Sendai traditional chest