Photo:Osaka Prefecture

Photo:Osaka Prefecture

- Wood, bamboo crafts

- Osaka

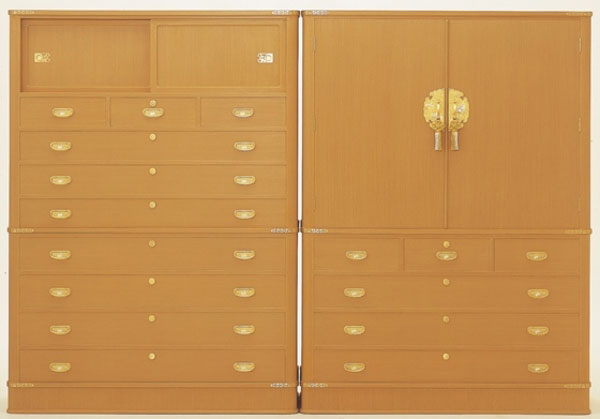

Osaka-senshu traditional paulownia chest Osaka senshu kiri tansu

Elegant and solid high-quality wood

made by the finest experienced artisans

Description

What is Osaka-senshu traditional paulownia chest ?

Osaka Senshu Kiri Tansu are wooden chests of drawers made in and around Kishiwada City and Sakai City, Osaka Prefecture. They are made from Paulownia wood, much appreciated for its durability, excellent moisture barrier properties and fire resistant properties. They have been a popular household item for a bride to bring to her new home on getting married, as they were long lasting, elegant and made of thick solid planks of good quality. Osaka Senshu Kiri Tansu are distinguished from many other paulownia chests in Japan by the quality of their high-level jointing techniques. With their delicate and graceful structure and being hand-made by artisans, they are sometimes praised as the best paulownia chests in Japan. Their production quantity is very small because of the high-level techniques required to make them, which further increases the rarity value of the impressively beautiful Osaka Senshu Kiri Tansu.

History

The origin of Osaka Senshu Kiri Tansu is not clearly known, but as the name of an artisan making tansu (chest of drawers) appears in Naniwazuru, a literary work written more than 300 years ago, it is assumed that the basis of the craft had already been established by the mid-Edo Period. During the Edo Period, as Osaka was located almost in the middle of Japan and due to the policies of the Edo shogunate, they had developed as an expanded urban area and became the center of commerce, earning the nickname of Tenka no Daidokoro meaning "Kitchen of the Country". The strong development of commerce in Osaka is considered to have had a significant influence on the production of Osaka Senshu Kiri Tansu in the late Edo Period. This is because tansu was necessary for storing a large number of articles in the land of commerce, and in addition, thanks to the development of agriculture in the Kinki region, the increasing number of prosperous farmers created a demand for kiri-tansu as status symbols to display their wealth.

General Production Process

- 1. Drying and sawing Excellent quality paulownia wood, such as those found in Aizu, Fukushima, are used to make Osaka Senshu Kiri Tansu. In recent years, due to over-felling in the country, there is a shortage of mature trees. Nowadays, logs from Virginia and Pennsylvania in the United States, which are close to Aizu in latitude, are increasingly used. Although such quality timber is very expensive, it is indispensable for making high quality Osaka Senshu Kiri Tansu. The logs are first sawn by checking their cross grain and straight grain, and the best way to make the most of the wood grain patterns is considered. The sawn wood is naturally dried for one to three years; exposure to wind and rain for a long period helps remove the lye and allows the wood to become an excellent quality wood with little discoloration.

- 2. Preparing the timber This is an important process in making Osaka Senshu Kiri Tansu. Planks are combined to best display their beautiful wood grain by constantly keeping in mind the appearance of the finished tansu.

- 3. Correction of warps As the wood dries it will naturally warp, and this is corrected by gently heating the wood over a fire and applying pressure.

- 4. Joining wood planks The joining process called the hagi process, unique to Osaka Senshu Kiri Tansu, is used to make wide wood planks. The sides of planks are glued and joined together. As the wood grains of the planks have to match when joined, this requires high-levels of skill.

- 5. Preparing the planks In this process, the planks are cut to the dimensions of parts including the tansu top board, the boards for the body part, drawers, hinged doors, and sliding doors. The surface of the wood planks are planed.

- 6. Joint process Mortise and tenon joints are prepared. The ends to be jointed are cut with a concavo-convex shape to allow assembly without nails or screws. Accurately cut tenons ensure no movement as the joint sections interlock to increase strength, making the tansu extremely durable and ensure a long-life.

- 7. Assembly of the body For the assembly of the body, dovetail slides are made. To assemble, the dovetail joints are tapped with a hammer, followed by a light planing to remove traces of assembly.

- 8. Drawers and sliding doors Drawers are made by fixing the bottom board with wooden nails. Sliding doors are made while closed. As even little gaps are not permitted for drawers and sliding doors, they are planed in units of 0.01 mm, which requires high-level planing techniques and skills.

- 9. Finishing In finishing, a small brush-like tool called uzukuri is used to bring out the wood grain, and a mixture of polishing powder and Alnus firma is used for coloring. By repeating the coloring process, the beautiful wood grain is increasingly burnished. A final wax polishing is given, followed by attaching selected fittings.

See more Wood, bamboo crafts

- Hakone wood mosaic

- Iwayado traditional chest

- Kaba cherrybark woodcrafts

- Odate bentwood

- Inami wood carvings

- Matsumoto furniture

- Beppu bamboo crafts

- Edo wood joinery

- Ichii woodcarvings

- Suruga bamboo crafts

- Edo bamboo fishing rods

- Kishu bamboo fishing rods

- Kamo traditional chest

- Kyo wood joinery

- Miyakonojo archery bows

- Osaka carved wooden panel

- Miyajima woodwork

- Nibutani carved wooden tray

- Okuaizu Basketry

- Echizen traditional chest

- Kasukabe traditional paulownia chest

- Katsuyama bamboo crafts

- Osaka karaki wood joinery

- Takayama tea whisks

- Toyooka wicker crafts

- Akita cedar tubs and barrels

- Nagiso woodturning

- Kishu traditional chest

- Nagoya traditional paulownia chest

- Osaka bamboo screens

- Osaka-senshu traditional paulownia chest

- Sendai traditional chest