Photo:Mikawachi ceramics industry cooperative

Photo:Mikawachi ceramics industry cooperative

- Ceramic

- Nagasaki

Mikawachi ware Mikawachi yaki

A beautiful blue world

made of fine details

Description

What is Mikawachi ware ?

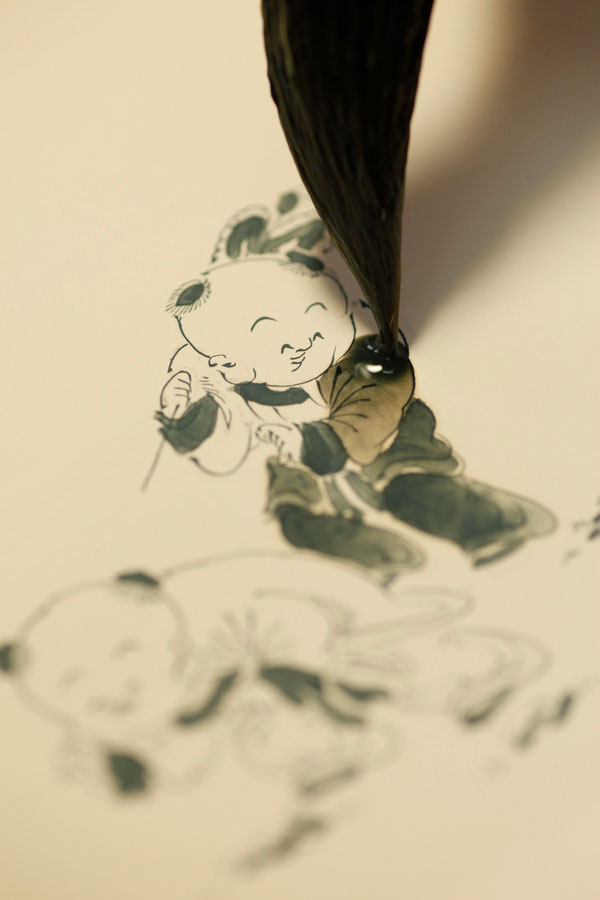

Mikawachi ware (called Mikawachi yaki in Japanese) is a form of porcelain produced around the city of Sasebo, in Nagasaki prefecture. Mikawachi ware has long been regarded as a high-class item due to its simple yet eyecatching blue dye on white porcelain. The pattern often used in Mikawachi ware is based on pictures of Chinese children playing. There are soft, round brushstrokes which generate a sense of warmth. Mikawachi ware was originally derived from China's Ming dynasty (1368-1644) with pictures of young boys meaning of prosperity and happiness. Unique versions of the young Chinese children playing have been drawn since the Meiji period (1868-1912).

The notable feature of Mikawachi ware is its production, which is delicate yet lively with techniques such as fretwork known as sukashibori or hand forming known as tebineri. This form of pottery, which is carefully crafted by hand one piece at a time, is popular not only as articles for daily use such as tableware, but also as gifts.

History

Photo:Mikawachi ceramics industry cooperative

Photo:Mikawachi ceramics industry cooperative

The leading theory is that Mikawachi ware has its roots in the Imjin war fought by Hideyoshi TOYOTOMI around the years 1592-1597. According to this theory, Shigenobu MATSURA, the lord of the Hirado domain governing the area around the city of Sasebo, brought back about one hundred Korean potters, including an important potter named Koseki, and had them open kilns. They mainly produced pottery at the beginning, but around the year 1640, white porcelain ore was discovered by Sannojo IMAMURA, Koseki's son, which started the gradual change to modern white porcelain.

Around the year 1650, the system of official business kilns was established, and the Hirado domain itself actively conducted patronage of Mikawachi ware. It is said that Mikawachi ware was presented as gifts to the Edo shogunate (feudal military government), and in the second half of 17th century attracted such attention domestically that it was exported to territories like China and Europe.

Mikawachi ware drew a line through the lives of common people, and has been widely used and loved by many since the Meiji period (1868-1912).

General Production Process

Photo:Mikawachi ceramics industry cooperative

Photo:Mikawachi ceramics industry cooperative

- 1. Stone crushing

Mikawachi ware uses Amakusa potter's stone, which is collected in the city of Amakusa, Kumamoto prefecture. This material is the source of the porcelain's whiteness. One day is spent finely grinding the potter's stone with a special machine until it becomes a powder.

- 2. Sedimentation tank

Since the crushed rock has different sizes and contains grains that are too large to use for porcelain, the grains must be separated by size.

When placed into water, grains of a larger size sink more quickly than smaller grains. Using this property, the crushed rock is dropped into a sedimentation tank and a filter tank is used to collect only fine-grain particles.

Then the collected fine grains are placed in a machine called a vacuum drain, which thoroughly removes air and produces clay.

- 3. Casting

The clay formed by the sedimentation tank is cast on a potter's wheel or by hand. Casting is an important factor in determining the shape of the porcelain.

Futhermore, there are various techniques applied during the casting stage when the pieces being made are ornaments. Techniques often used in Mikawachi ware are sukashi bori to curve and bore holes, tebineri to express lively animals and vegetation and pasting to attach the items to other pieces of unglazed pottery.

- 4. Drying

The potter's clay is then thoroughly dried in the sunlight and the rough parts of the surface are shaved to produce a smooth surface.

- 5. Bisque

The bisque firing, the first firing before any glaze is applied, is done for around seven hours at a high temperature of 900℃ (about 1292℉).

Bisque firing is carried out in order to make it easier to perform the next process, which is decorative coating.

- 6. Undercoating

After the bisque firing, the ceramics are not necessarily pure. If dust is attached to the surface, it will be mixed up with the paint and there is a risk that the item will be ruined. Therefore, before undercoating is applied, dust is removed by thoroughly polishing with a dry cloth.

For this process, an asbolite pigment is used. Painting is performed with care using a writing brush. Asbolite is a grayish color at the undercoating stage, but when fired it becomes a marvelous vivid blue dye.

After the undercoating, a thick brush is used to apply dark asbolite called dami in order to express shading.

- 7. Glazing

After applying an undercoat, enamel is applied all over. By applying the enamel, a glass-like transparency is produced and strength is reinforced.

- 8. Glaze firing

Then, once the enamel has been thoroughly applied all over, pieces are fired for fifteen to twenty hours at around 1300℃ (around 2372℉), which is even higher than the temperature used in bisque firing.

A particularly important part is after the glaze firing process. Cracks will be found if the pieces are suddenly taken away from a high temperature place to a room temperature place. To avoid that, the pieces are cooled over time before being removed from the kiln.

- 9. Overcoating

Mikawachi ware with its characteristic vivid blue, is often inspected after glaze firing and sent out. However, there can be an overcoat when further coloring like red or another color is applied.

After the overcoating, the pieces are thoroughly baked by glaze firing, which involves firing at around 750℃ (1382℉) for approximately seven hours to settle the coloring.

Where to Buy & More Information

Mikawachiyaki Museum

Photo:Nagasaki Photo Studio

Photo:Nagasaki Photo Studio

-

Address

-

Tel.+81-956-30-8080

-

ClosedDecember 29 to January 3

-

Business Hours9am to 5pm

-

Website

See more Ceramic

- Imari ware/Arita ware

- Hasami ware

- Kutani ware

- Mashiko ware

- Shigaraki ware

- Bizen ware

- Hagi ware

- Koishiwara ware

- Mino ware

- Tobe ware

- Tokoname ware

- Karatsu ware

- Kasama ware

- Satsuma ware

- Iga ware

- Mikawachi ware

- Agano ware

- Otani ware

- Obori-soma ware

- Tsuboya ware

- Aizu-hongo ware

- Shodai ware

- Echizen ware

- Akazu ware

- Tamba-tachikui ware

- Yokkaichi-banko ware

- Izushi ware

- Kyo ware/Kiyomizu ware

- Iwami ware

- Amakusa ceramics

- Seto-sometsuke ware

- Sanshu Onigawara Crafts