- Ceramic

- Tokushima

Otani ware Otani yaki

A unique production method of

the finest large ceramic pieces in Japan

Description

What is Otani ware ?

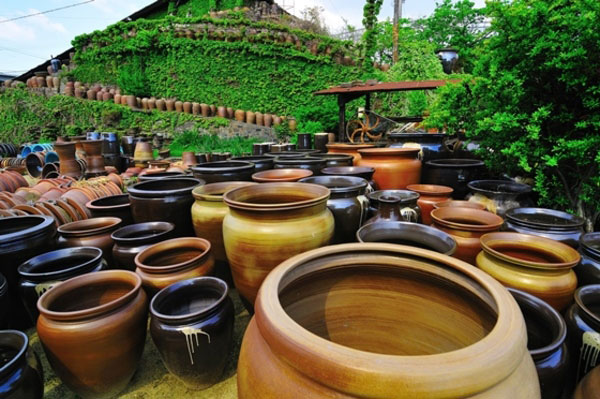

Otani ware (called Otani yaki in Japanese) is a form of ceramics that is the most famous product of the city of Naruto in Tokushima prefecture, and is the representative craft for the prefecture.

The notable characteristics of Otani ware are its simple textured clay and its nerokuro technique. The clay used for Otani ware is Hagiwara clay collected locally in the area of Oasacho, Tokushima prefecture. This clay has a high iron content, and many people love its rough texture and faint luster. Nerokuro is a casting technique which name meaning "lying down lathe", is derived from the fact that the artisan lies beneath the pottery wheel and kicks it when producing pieces like large jugs that are the height of an adult. Also, the climbing kilns* used to bake large ceramics are said to be the biggest kilns in Japan. There is a wide variety of Otani ware products: besides large ceramics, there are also pieces used in everyday life, such as rice bowls and teacups, and all kinds of ornamental products. Dark brown pottery is the mainstream, but there are also deep silver and gray pieces.

*A climbing kiln is an ancient type of pottery kiln brought to Japan from China and Korea.

History

Otani ware is said to have begun in 1780, when a porcelain craftsman visited Otanimura (now the city of Naruto) and produced pottery with red clay by means of lathe work.

In 1781, the lord of the domain took an interest in pottery and ordered that a domain managed kiln be established in Otanimura. Thus the first dyed porcelain came to be produced in what is now Tokushima prefecture. However the cost of materials led the kiln to be shut down in three years.

In 1784, the work of indigo dye merchant Bungoro KAYA led to a connected climbing kiln (formed by digging a hole in the hillside) being built in Otanimura as a national kiln for the baking of daily-use pottery.

Production of pottery began at this climbing kiln, emphasizing Heijibei NODA, who had obtained techniques by employing Shigaraki ware artisans from Shiga prefecture. This was the prototype for modern-day Otani ware.

General Production Process

- 1. Grinding

The raw material of clay is collected and ground into fine pieces after drying.

- 2. Sieving

The ground clay is sieved and refined by removing impurities.

- 3. Elutriation

After purification, the clay is placed inside a water tank and the stirring process begins. While stirring, the clay is gradually transferred by pouring the soil into another water tank

Once the transfer has been completed, all of the foreign matter is caught in a sieve, and then left for a while until the potter's clay that forms the raw material for porcelain settles. The settled potter's clay is moved to a pot and left until it becomes moderately hard.

- 4. Clay kneading

The artisan steps barefooted on top of round shaped potter's clay, using both feet to tread so as to push out the clay. This process, called araneri kneading, is carried out to make the whole piece of clay evenly soft.

Next kikuneri kneading is done with the hands in order to extract air bubbles from inside the clay while rotating clay that has already been kneaded by foot.

- 5. Casting

The clay is moved onto a lathe, where it is shaped by hand.

When producing large ceramics, artisans work in pair to use Otani ware's traditional nerokuro casting technique to produce casts. One artisan lays down with their feet against the cast while the other one stands next to the piece.

- 6. Drying

Pieces that have been cast are then dried indoors in the shade. When producing large ceramics such as jugs and pots, the drying process will take about twenty days. For small pieces of pottery, drying typically requires between two and seven days.

Next, the pieces are moved outdoors to be dried under sunlight. Here, large pieces are dried for around two or three days, and small pieces are typically dried in about one day.

- 7. Glazing

Once the pieces have been dried under sunlight, the next step is to glaze with enamel.

There are three main methods of glazing: namagake, in which enamel is applied without bisque firing*; hitashigake, where articles are soaked in enamel after bisque firing; and nagashigake, where enamel is poured over the pieces using a ladle.

In addition, the bisque process takes between eight and sixteen hours in a kiln at a temperature of around 800℃ (about 1472℉).

*Bisque firing is an initial firing done at a low temperature before any glaze is applied.

- 8. Loading pots into the kiln

The pots are neatly placed in the kiln for baking.

- 9. Firing

The kiln temperature is set to around 1230℃ (about 2246℉) before moving on to the firing process in which the pieces are baked.

There are three types of kiln: climbing kilns, electric kilns, and gas kilns. The period of time required for firing is different in each type of kiln.

For climbing kilns, five to six days and nights are required, while electric kilns and gas kilns require one to two days.

- 10. Inspection

The items are removed from the kiln and checked for chips and cracks.

- 11. Completion

Only items that have passed the inspections are sold as finished pieces.

Where to Buy & More Information

Onishitoki LLC.

-

Address

-

Tel.+81-88-689-0414

-

ClosedWednesdays

-

Business Hours9am to 5pm

-

Website

See more Ceramic

- Imari ware/Arita ware

- Hasami ware

- Kutani ware

- Mashiko ware

- Shigaraki ware

- Bizen ware

- Hagi ware

- Koishiwara ware

- Mino ware

- Tobe ware

- Tokoname ware

- Karatsu ware

- Kasama ware

- Satsuma ware

- Iga ware

- Mikawachi ware

- Agano ware

- Otani ware

- Obori-soma ware

- Tsuboya ware

- Aizu-hongo ware

- Shodai ware

- Echizen ware

- Akazu ware

- Tamba-tachikui ware

- Yokkaichi-banko ware

- Izushi ware

- Kyo ware/Kiyomizu ware

- Iwami ware

- Amakusa ceramics

- Seto-sometsuke ware

- Sanshu Onigawara Crafts