- Woven textiles

- Yamagata

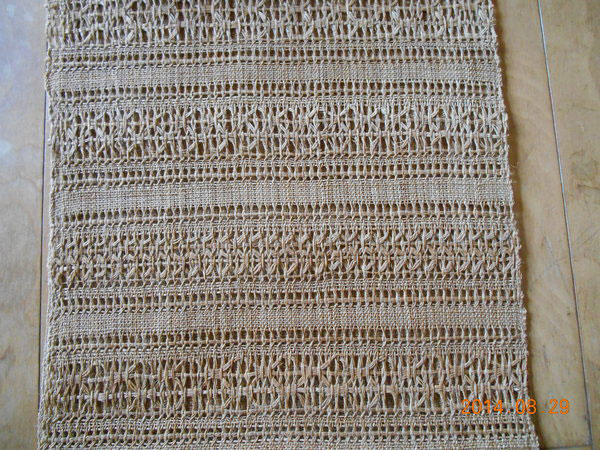

Oitama tsumugi silk Oitama tsumugi

Beautiful plain elegant fabrics

Three distinct regional techniques

Description

What is Oitama tsumugi silk ?

Oitama tsumugi is a silk fabric produced in the Yonezawa, Hakutaka and Nagai regions of Oitama in southern Yamagata prefecture. The area was well-known for producing and exporting ramie, a tall plant of the nettle family that has been used to make fabric for centuries, since the beginning of the Edo period (1603-1868). From the end of this period, efforts were made to establish self-sufficient fabric production. Then, the use of ramie came to be replaced by locally produced mulberry silk and the region shifted to silk fabric production.

The techniques and methods for Oitama tsumugi vary based on the region, whether it is Yonezawa, Hakutaka or Nagai. Yonezawa is known for using natural dyes like safflower (the prefectural flower of Yamagata), indigo and silvergrass. Hakutaka uses itajime or a wooden board resist dying method, which is unique to the area. Also kasuri patterns* were strongly influenced by fabric produced in Okinawa. Each region has differing production processes but they all use the same techniques of dyeing before weaving and plain weaving, which is labor intensive.

* Kasuri patterns are the precise patterning and images that result from a technique of wrapping fibers with thread in order to dye specific threads of fabric.

History

Farmers in Yonezawa cultivated ramie and safflower plants during the early Edo period. In 1601, Kagekatsu UESUGI, the lord of the Yonezawa domain (modern day Yamagata), encouraged his subjects to cultivate them as exclusive products of the region. They were shipped to Echigo (now Niigata) and other regions as raw material for producing fabric. In 1776, Yozan UESUGI (ninth lord of the Yonezawa domain) started inviting artisans from Echigo to help with starting a fabric production industry by teaching weaving techniques to the local women.

At first, the textile was produced from ramie but the reformation of the domain encouraged more sericulture, and production gradually shifted to silk fabrics. Furthermore, in the Meiji period (1868-1912), silk fabric production spread to the nearby regions of Hakutaka and Nagai, which also had a successful silk industry. The advanced technique of making kasuri patterns was introduced and taught in these regions. Yoneryu kasuri and Itajime kogasuri became well known throughout Japan between the Taisho period (1912-1926) and the early Showa period (1926-1989). From 1976, the three regions unified their fabric production and the techniques of Kusakizome from Yonezawa, Yokoso kasuri and Tateyoko Heiyo kasuri from Nagai, and Itajime kogasuri from Hakutaka have been known as Oitama tsumugi.

General Production Process

- Natural plant dyeing method (Yonezawa tsumugi kusakizome)

- 1. Picking safflowers Safflower, which is similir to thistle, blooms bright yellow flowers in the summertime. Between the beginning and middle of July, however, the flowers become reddish and are picked in the early morning when the thorns have been softened by the morning dew.

- 2. Kneading in water

The safflower petals change their color from yellow to orange when they are kneaded in water. The yellow pigment dissolves and is easily isolated in water, while the red pigment is not as water-soluble and tends to remain in the petals.

- 3. Fermentation

Drying and fermenting the petals increases the red pigment by about ten times, and crushing them in a mortar and pestle intensifies the color even more.

- 4. Producing safflower cakes

The safflower petals are pounded to make flat safflower cakes, which are dried for ease of transportation and dye adjustment to control the depth of color.

- 5. Dissolving of pigment and dyeing

The safflower cakes are soaked in lye to dissolve the pigment. Threads are dyed an orange color, which changes to bright red after acid is applied. This step is repeated until the desired shade is attained.

- Wooden board resist dyeing method (Itajime kogasuri)

- 1. Reeling silk from cocoons

The warp (perpendicular) threads and the weft (parallel) threads are prepared by teasing out fibers from the boiled cocoons and hand winding them to give the threads a natural texture.

- 2. Winding the threads around a special board

For the Itajime dying method, the warp and weft threads are wound around special boards with fine grooves carved in accordance with Kasuri patterns. Any discrepancy in the tension of the threads will affect the positioning of the patterns so this is an important process that demands great care and concentration.

- 3. Dying the threads

About ten boards with wound threads are stacked one on top of the other and temporarily tightened on the top and the bottom. Hot water is poured over the boards to fuse the boards and threads, then natural dye is poured over them. When the boards are removed, the threads are will have been dyed with the same patterns as the grooves on the boards.

- 4. Weaving

The dyed threads are left to dry and then woven by adjusting the threads so the patterns on the warp and weft threads are in their correct positions. Weaving requires great concentration as even a skilled weaver cannot weave more than thirty centimeters a day. This precise and detailed work produces the delicate patterns of Itajime kasuri.

Where to Buy & More Information

Yonezawa Orimono Rekishi Shiryokan

-

Address

-

Tel.+81-238-22-1325

-

ClosedDecember 29 to January 1

-

Business Hours9am to 5pm

-

Website

See more Woven textiles

- Nishijin brocade

- Yuki tsumugi silk

- Kurume traditional resist-dyed textiles

- Ojiya chijimi textiles

- Hakata brocade

- Ushikubi tsumugi silk

- Chichibu-meisen silk

- Miyako ramie textile

- Shiozawa tsumugi silk

- Kumejima tsumugi silk

- Omi ramie cloth

- Ryukyu traditional resist-dyed textiles

- Kiryu brocade

- Murayama-oshima tsumugi silk

- Yumihama traditional resist-dyed textiles

- Chibana-hanaori textiles

- Hon-shiozawa silk

- Oitama tsumugi silk

- Ojiya tsumugi silk

- Yaeyama cotton cloth

- Yaeyama ramie cloth

- Honba oshima tsumugi silk

- Shinshu tsumugi silk

- Shuri brocade

- Tama brocade

- Yomitanzan-hanaori textiles

- Isesaki traditional resist-dyed textiles

- Hachio island silk

- Nibutani bark cloth

- Uetsu tilia bark cloth

- Awa-shijira cotton cloth

- Kijoka banana fiber cloth

- Tokamachi traditional resist-dyed textiles

- Tokamachi akashi chijimi textiles

- Yonaguni brocade

- Yuntanza minsa

- Flower pattern textiles

- Oku-Aizu Showa Karamushi Textiles