- Woven textiles

- Niigata

Ojiya chijimi textiles Ojiya chijimi

First-class textiles for the summer

Loved by all generations

Description

What is Ojiya chijimi textiles ?

Ojiya chijimi textiles (called Ojiya chijimi in Japanese) is a handicraft produced from ramie in the area around the city of Ojiya in Niigata prefecture. Ramie is a tall plant of the nettle family that has been used to make cloth for centuries. Ramie cloth has little tolerance for dry air, so a level of humidity must be maintained during the production process. Because ramie threads break easily when the air is dry, this region being surrounded by snow and maintaining just the right humidity makes it suitable for production. The most notable feature of Ojiya chijimi is the process of exposing the fabric to snow, which utilizes the bleaching effect from ozone produced when snow evaporates in the sun.

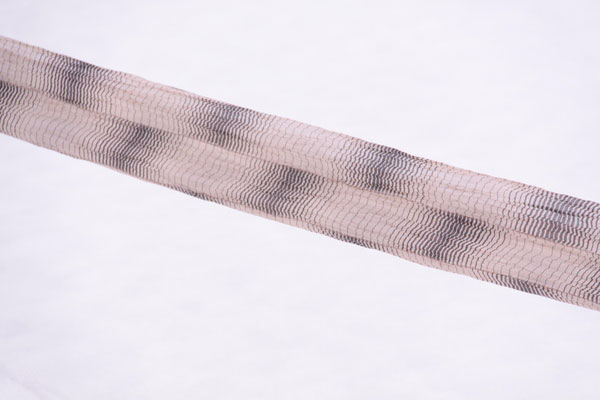

The cloth is known for its shibo or bumpy texture, which is created after unwinding tightly twisted yarns. The ramie material encourages the evaporation of sweat and dries quickly, so kimono made from it have a pleasantly cool feeling. Because of the natural wrinkling, Ojiya chijimi kimono have a refreshing texture which is excellent during the intense humidity of Japanese summers, making it popular throughout the country.

History

Out of all of the fabrics made from traditional materials like silk, linen, hemp, or ramie, Echigo jofu linen is one that has long been popular among ordinary people in the area around Niigata prefecture. It is said that Ojiya chijimi textile is an improved version of Echigo jofu textiles which has existed for over one thousand years. Echigo jofu texiles have such a long history that the Shosoin Repository* possesses ancient manuscripts with its description. Since ancient times, Echigo jufu has been a luxury item that was often given as a gift to the top military commander (shogun) and imperial court.

Ojiya chijimi production began around 1670, during the Edo period (1603-1868) when a feudal bureaucrat of the Akashi clan, Masatoshi HORIJIROU started the industry based on the Echigo Jofu tradition and Akashi chijimi production techniques. It soon spread throughout the neighboring Uonuma region and peaked in the Edo period, with an annual production of around 200,000 rolls.

Women primarily take on the role of producing Ojiya chijimi and Echigo jofu, and the techniques have been passed down from one generation to the next, from mother to daughter or mother-in-law to wife.

However, with the introduction of modern machinery after the Meiji Period (1868-1912), hand production began to decline. Fortunately, the traditional techniques were preserved and high-quality ramie textiles are still produced today.

*The Shosoin Repository is a building located in Nara, a former capital of Japan, that has been around since the eighth-century. It not only has a collection of treasures dating back to the Silk Road, it also preserves over 10,000 hand-written documents all dating from the Nara period (710–784). Today the repository is under the control of the Imperial Household Agency.

General Production Process

- 1. Designing splash patterns

At first, Ojiya chijimi requires a high degree of meticulous planning and calculation. This involves drawing a rough draft of splash patterns, deciding where to place the patterns on graph paper, and creating an overall design. Tiny cuts are made to trace the patterns and enable the design to be divided into several slips. To mark the sections of yarn to be dyed, patterns are copied using a ruler that represents the weft pattern. After repeating this process, many rulers are created to represent the whole design.

- 2. Thread making

The fabric for Ojiya chijimi is ramie grown in Showa village in Fukushima prefecture. Ramie was once cultivated in Niigata prefecture, but with a change in governing feudal lord, the tradition moved to the Aizu region of Fukushima prefecture. Harvested ramie is soaked in water before the long bark fibers are peeled and left to dry. Warp or the parallel threads are twisted more strongly and the weft or perpendicular threads are twisted more loosely so that wrinkles in the fabric develop more easily.

- 3. Hand-stretching of warps and wefts

Warp threads are spread on a table, adjusted for length, and counted according to the design. A fixed number of wefts are removed from a wire spool and aligned on the table. The patterning process threads are prepared. Ojiya chijimi textile is also known as yokosougasuri, denoting designs composed of plain warps and splash patterned wefts.

- 4. Ink marking, Kubiri (tie-dye)

Black ink is used to mark where to create patterns according to rulers or paper slips. The marked parts of threads are tightly tied with string to prevent dye penetrating and to create the splash patterns on the wefts.

- 5. Dyeing

After ink marking, dyes are rubbed into yarns with a spatula and crumpled repeatedly to ensure the dyes have soaked well. Then they are steamed at 100ºC (212℉) to fix the colors.

- 6. Weaving

After dyeing, the threads are set on a loom with warps and wefts laid according to the pattern. First the warps are individually tied into heddle stitches and the wefts are wound around a hand-spun reel, before being set on a board and wound onto a tube. The next step is weaving, an important process requiring constant checking of the pattern.

- 7. Finishing touches

The last process is yumomi (washing in tepid water), and is unique to Ojiya chijimi. After hand-washing to make an uneven surface and bring out the wrinkly texture, the cloth is trodden on by feet to soften it and ensure any glue or stains are removed. Finally the cloth is laid on the snow to dry in the sun as this has a natural bleaching effect and brings out the beauty of the colors and patterns.

Where to Buy & More Information

Ojiya Dento Sangyo Kaikan Sunplaza

-

Address

-

Tel.+81-258-83-4800

-

ClosedDecember 29 to January 3

-

Business Hours9am to 4pm

-

Website

See more Woven textiles

- Nishijin brocade

- Yuki tsumugi silk

- Kurume traditional resist-dyed textiles

- Ojiya chijimi textiles

- Hakata brocade

- Ushikubi tsumugi silk

- Chichibu-meisen silk

- Miyako ramie textile

- Shiozawa tsumugi silk

- Kumejima tsumugi silk

- Omi ramie cloth

- Ryukyu traditional resist-dyed textiles

- Kiryu brocade

- Murayama-oshima tsumugi silk

- Yumihama traditional resist-dyed textiles

- Chibana-hanaori textiles

- Hon-shiozawa silk

- Oitama tsumugi silk

- Ojiya tsumugi silk

- Yaeyama cotton cloth

- Yaeyama ramie cloth

- Honba oshima tsumugi silk

- Shinshu tsumugi silk

- Shuri brocade

- Tama brocade

- Yomitanzan-hanaori textiles

- Isesaki traditional resist-dyed textiles

- Hachio island silk

- Nibutani bark cloth

- Uetsu tilia bark cloth

- Awa-shijira cotton cloth

- Kijoka banana fiber cloth

- Tokamachi traditional resist-dyed textiles

- Tokamachi akashi chijimi textiles

- Yonaguni brocade

- Yuntanza minsa

- Flower pattern textiles

- Oku-Aizu Showa Karamushi Textiles

See items made in Niigata

- Ojiya chijimi textiles

- Shiozawa tsumugi silk

- Hon-shiozawa silk

- Ojiya tsumugi silk

- Niigata lacquerware

- Kamo traditional chest

- Murakami carved lacquerware

- Tsubame-tsuiki copperware

- Echigo-sanjo cutlery

- Tokamachi traditional resist-dyed textiles

- Nagaoka Buddhist altar

- Tokamachi akashi chijimi textiles

- Echigo-yoita cutlery

- Sanjo Buddhist altar

- Niigata-shirone Buddhist altar