Photo:Okinawa Prefecture

Photo:Okinawa Prefecture

- Woven textiles

- Okinawa

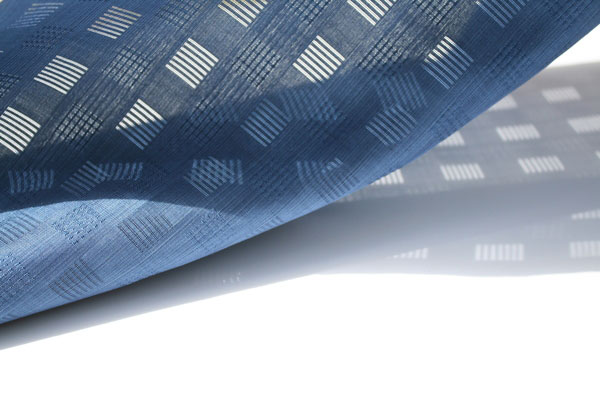

Shuri brocade Shuri ori

Versatile designs nurtured by the southern climate

Exquisite textile loved by the aristocracy of Okinawa

Description

What is Shuri brocade ?

Shuri brocade (called Shuri ori in Japanese) is a woven fabric produced on the main island of Okinawa. There are two types of fabric, kasuri orimono and mon orimono, and these include hanaui, hanakura ori, doton ori, kasuri and minsa. The Ryukyu dynasty (current day Okinawa) was active in trade with China and Southeast Asia from the 14th to 15th century which brought in many weaving techniques. Shuri brocade is woven with silk, cotton, hemp or banana fiber threads, and dyed with plant dyes including Ryukyu ai (indigo), fukugi tree, shibuki, tekachi and guru. This craft has a wide variety of textiles suitable for Okinawa's climate. Hanakura ori and doton ori, used to be woven only in Shuri (former capital of Ryukyu), and were designated as specific fabrics for the royal family and aristocrats. Hanakura ori is a yarn-dyed figured fabric mainly using solid colors such as yellow, blue and dark blue and gradations of color in its design. Doton ori, is abundant in color variations on an indigo base and was used for men's clothes in the Ryukyu dynasty period. Currently, it is used for kimono belts and accessories.

History

Photo:Okinawa Prefecture

Photo:Okinawa Prefecture

The Ryukyu dynasty had flourishing trade with China and Southeast Asia between the 14th and 15th centuries when weaving techniques were introduced. The climate of Okinawa led artisans to develop original styles. In Shuri, the old capital of the Ryukyu dynasty, weaving techniques, colors, designs, elegance, and style were especially developed as a result of weaving cloth dedicated to the royal family and aristocrats. Shuri brocade has been passed down for generations in the royal family and among upper-class women. The processes of Shuri brocade are not divided but manufactured in one continuous process by hand, so the artisans are able to produce only a small amount but various types of fabric. In spite of losing everything during World War II, the long heritage of Shuri brocade in Okinawa has been cherished up to today. Patterns that feature the nature and animals of Okinawa originate from their unique kasuri technique. Ryukyu kasuri is believed to be one of the roots of kasuri in Japan and has influenced other kasuri production regions.

General Production Process

Photo:Okinawa Prefecture

Photo:Okinawa Prefecture

- 1. Design

Various textiles woven in Okinawa such as hanakura ori, hanaui, doton ori and minsa are collectively called Shuri brocade. The production process of kasuri spread and had influence throughout Japan. It is said that Shuri kasuri is precursor of kasuri because of its unique hand-wound technique.

The designs are based on a traditional design book that was edited by an artist for the royal family in Shuri. A traditional design pattern with a contemporary feel is chosen.

- 2. Thread winding

Itokuri or thread winding is done after removing impurities, boiling the threads in hot water to strengthen warps (parellel threads), sizing them, and starching them.

- 3. Warping

Warping is formatting the number and the length of threads to weave a bolt of cloth.

- 4. Warp tying

Warp tying (kasuri kukuri in Japanese) is a process of marking the vertical threads (warps) stretched according to the design and manually binding specific parts to avoid being dyed to make the kasuri. A special weaving loom is required to create a pattern featuring complicated, delicate patterns that are difficult to make manually. The number and the length of horizontal threads (wefts) depends on the design pattern. During this process, a loom wider than a bolt of cloth is used to set up the threads on a frame where the threads are marked according to the design, and then manually binded.

- 5. Dyeing

Shuri brocade fabrics are mainly dyed with plants that are found in Okinawa, such as Ryukyu indigo, Yeddo hawthorn, and fukugi trees. The plant for Ryukyu indigo (Ryukyu ai) originated in Southeast Asian countries. Indigo plants have been believed from ancient times to be insect-repelling which is why it was used for clothing and daily use goods.

It takes a week in summer and two weeks in winter to make indigo dye. Dye production involves a process that adds water solubility to indigo leaves to make the solution which becomes dyeable when the flowers turn red. The threads are tied and immersed in the vat of dye and rubbed gently, letting the dye absorb. Then the threads are wrung, oxidized with air, and dried in direct sunlight. Dyeing requires patience because the same steps are repeated multiple times. Shuri brocade has a golden color which is extracted from the bark of fukugi.

- 6. Preparation for weaving

The dyed threads are untied, aligned, and stretched on the loom according to the design pattern. The design sequence of kasuri threads is inserting kasuri threads, stripe threads and ground threads, temporary reeding, winding, heddle drawing, and reeding. Aligned weft threads are spooled around the tube which fits into the shuttle.

- 7. Weaving

Skilled artisans weave Shuri brocade by hand using a wood loom called takahata. Even an experienced weaver will take a day to complete 30㎠ of fabric as this is a complicated process. The weft threads are set in a shuttle and meticulously woven according to the design. After weaving, the brocade is washed, stretched out to dry, and the fabric is complete.

Where to Buy & More Information

Naha Traditional Craft Center

Photo:Okinawa Convention & Visitors Bureau

Photo:Okinawa Convention & Visitors Bureau

-

Address

-

Tel.+81-98-868-7866

-

ClosedWednesdays and December 29 to January 3

-

Business Hours9:30am to 5:30pm

-

Website

See more Woven textiles

- Nishijin brocade

- Yuki tsumugi silk

- Kurume traditional resist-dyed textiles

- Ojiya chijimi textiles

- Hakata brocade

- Ushikubi tsumugi silk

- Chichibu-meisen silk

- Miyako ramie textile

- Shiozawa tsumugi silk

- Kumejima tsumugi silk

- Omi ramie cloth

- Ryukyu traditional resist-dyed textiles

- Kiryu brocade

- Murayama-oshima tsumugi silk

- Yumihama traditional resist-dyed textiles

- Chibana-hanaori textiles

- Hon-shiozawa silk

- Oitama tsumugi silk

- Ojiya tsumugi silk

- Yaeyama cotton cloth

- Yaeyama ramie cloth

- Honba oshima tsumugi silk

- Shinshu tsumugi silk

- Shuri brocade

- Tama brocade

- Yomitanzan-hanaori textiles

- Isesaki traditional resist-dyed textiles

- Hachio island silk

- Nibutani bark cloth

- Uetsu tilia bark cloth

- Awa-shijira cotton cloth

- Kijoka banana fiber cloth

- Tokamachi traditional resist-dyed textiles

- Tokamachi akashi chijimi textiles

- Yonaguni brocade

- Yuntanza minsa

- Flower pattern textiles

- Oku-Aizu Showa Karamushi Textiles

See items made in Okinawa

- Tsuboya ware

- Miyako ramie textile

- Ryukyu lacquerware

- Kumejima tsumugi silk

- Ryukyu traditional resist-dyed textiles

- Chibana-hanaori textiles

- Yaeyama cotton cloth

- Yaeyama ramie cloth

- Shuri brocade

- Yomitanzan-hanaori textiles

- Ryukyu traditional textiles

- Kijoka banana fiber cloth

- Yonaguni brocade

- Yuntanza minsa

- Flower pattern textiles

- Sanshin