Photo:Okinawa Prefecture

Photo:Okinawa Prefecture

- Woven textiles

- Okinawa

Chibana-hanaori textiles Chibana hanaori

Exquisite textile with a long history

that makes best use of the cultural heritage

Description

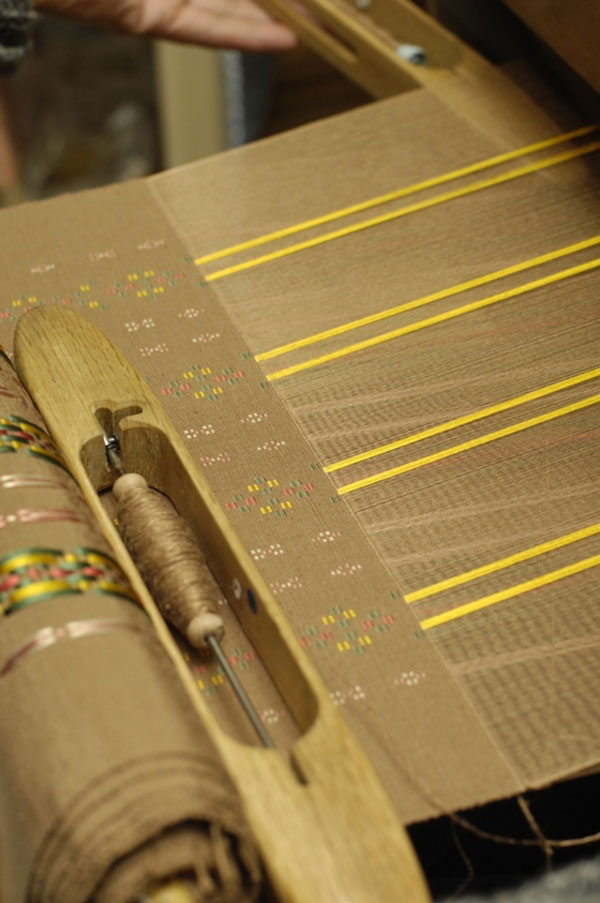

What is Chibana-hanaori textiles ?

Chibana hanaori is a textile produced in Chibana, Okinawa, Okinawa prefecture. It has flowery patterns woven in the base textile as well as a continuous geometric pattern. This kind of textile with a continuous geometric pattern is called mon orimono, and its gorgeous pattern is thought to have been brought from South Asia.

There are two kinds of Chibana hanaori textiles: tate uki hanaori, in which patterns appear vertically and nui-tori hanaori, in which the patterns woven look as though they are embroidered. The raw material is mainly cotton but there were times when silk and wool were also used. Normally, a textile design uses the same pattern woven continuously for the whole length of the kimono fabric. However, sometimes Chibana hanaori would have different patterns at the beginning and end. This was because the craft was not subject to tax collection, although there were many textiles given as gifts to the government in lieu of tax payment in cash during the Ryukyu Kingdom period (early 15th century-1879.) Chibana hanaori has been and continues to be worn for important ritual events.

History

Photo:Okinawa Prefecture

Photo:Okinawa Prefecture

The origin of Chibana hanaori is unclear. It is thought to have been first woven in the region surrounding former Misato-Mura (now the city of Okinawa) around the 18th century. At that time, the Ryukyu Kingdom was actively trading with China and South Asian countries, therefore, the craft is thought to be originally from South Asia. Chibana hanaori was not used as a gift to the royal government so the designs of the textile could be woven freely and worn for ritual events to pray for a big harvest, such as Umaharashi (a horse race) and Usudeku (a traditional festival where women dance). However, the production of Chibana hanaori declined rapidly after the Meiji period (1868-1912) started.

Okinawa had catastrophic damage during the Second World War and Chibana hanaori production techniques completely died out. Fortunately, the craft was revived for the first time in 100 years in 1989. Now, the government supports protecting and preserving production techniques so the textile is actively produced not just for kimono material but also for accessories like men’s ties.

General Production Process

Photo:Okinawa Prefecture

Photo:Okinawa Prefecture

- 1. Design

The design of the textile is decided with graph paper.

- 2. Winding threads

The threads are wound around a wooden bobbin.

- 3. Warping

The warp threads are sorted into the length and width that is required for a roll of textile.

- 4. Dyeing the threads

Natural materials are used to extract dyes. Ryukyu ai (indigo native to Okinawa) is used for dyeing the base of the textiles a shade of navy blue that is specific to Okinawa. When the threads are dyed multiple times in indigo dye, which has been fermented in Awamori (a strong liquor), it becomes a deep navy blue. Fukugi (happiness tree) and Yeddo hawthorn are used to produce yellow and red for the pattern. Fukugi are trees in Okinawa that are planted in the garden to protect against wind. The bark and leaves of Fukugi are used to extract dye. Yeddo hawthorn are trees that are rich with tannin, which produces a brownish-red color.

- 5. Temporarily putting the threads through reed

The dyed threads are put through to the fine grooves of the reed one by one. The reed is used for the preparation process before weaving and it is removed when weaving starts. This process sorts the colored threads and the foundation threads by inserting the sorted threads through the reed, temporarily.

- 6. Putting the threads through the heddle

The boards are removed and the threads are put through the heddle, which is the part that moves threads up and down. The top thread and bottom thread are kept separately in the heddle so that the weft thread can pass between the top and the bottom thread. The textile is woven by crossing the threads in an alternating pattern.

- 7. Putting through the threads for actual weaving

The warp threads are put through the reed again. The top and the bottom threads are set separately to put them through the reed.

- 8. Weaving

The weft threads are passed in accordance with the design while weaving. The textile is woven using the technique of tate uki hanaori, which produces the patterns vertically, and nui-tori hanaori, which weaves the textile as though it is embroidered.

- 9. Washing and drying

When the textile is woven, it is washed and stretched out to dry. The temple is a curved pole and it pulls the textile sideways to prevent it from shrinking so that the the width and length of the textile is even and as specified.

See more Woven textiles

- Nishijin brocade

- Yuki tsumugi silk

- Kurume traditional resist-dyed textiles

- Ojiya chijimi textiles

- Hakata brocade

- Ushikubi tsumugi silk

- Chichibu-meisen silk

- Miyako ramie textile

- Shiozawa tsumugi silk

- Kumejima tsumugi silk

- Omi ramie cloth

- Ryukyu traditional resist-dyed textiles

- Kiryu brocade

- Murayama-oshima tsumugi silk

- Yumihama traditional resist-dyed textiles

- Chibana-hanaori textiles

- Hon-shiozawa silk

- Oitama tsumugi silk

- Ojiya tsumugi silk

- Yaeyama cotton cloth

- Yaeyama ramie cloth

- Honba oshima tsumugi silk

- Shinshu tsumugi silk

- Shuri brocade

- Tama brocade

- Yomitanzan-hanaori textiles

- Isesaki traditional resist-dyed textiles

- Hachio island silk

- Nibutani bark cloth

- Uetsu tilia bark cloth

- Awa-shijira cotton cloth

- Kijoka banana fiber cloth

- Tokamachi traditional resist-dyed textiles

- Tokamachi akashi chijimi textiles

- Yonaguni brocade

- Yuntanza minsa

- Flower pattern textiles

- Oku-Aizu Showa Karamushi Textiles

See items made in Okinawa

- Tsuboya ware

- Miyako ramie textile

- Ryukyu lacquerware

- Kumejima tsumugi silk

- Ryukyu traditional resist-dyed textiles

- Chibana-hanaori textiles

- Yaeyama cotton cloth

- Yaeyama ramie cloth

- Shuri brocade

- Yomitanzan-hanaori textiles

- Ryukyu traditional textiles

- Kijoka banana fiber cloth

- Yonaguni brocade

- Yuntanza minsa

- Flower pattern textiles

- Sanshin